Fluidics

With 50 years of valve manufacturing experience and a strong presence in commercialized analytical, in-vitro diagnostic, and life science instrumentation, IDEX Health & Science offers you customized solutions to reliably direct fluid across your platform.

Image A

Image B

There are several scenarios where you may want to guide fluids across multiple areas of your platform. A selector valve allows for the connection of a center common port to any of the outer ports allowing flow either from the center common ports to the outer ports or from the outer ports to the center common port. These valves are commonly implemented in applications such as:

For all these applications and more, IDEX Health & Science has a solution for you. We can help you customize a solution to easily select and direct fluid across your instrument. With our Rapid Valve Prototype program, we can provide a custom concept demonstration unit in less than six weeks. Capable of controlling up to 24 separate fluid streams, our valves come in a wide variety of materials (bioinert and metal options), and pressure capabilities, so you can find the customized solution to meet your needs.

An injection valve allows you to load samples into one port into a holding loop of a fixed volume. When appropriate, the valve will rotate to introduce the loop into the analytical fluid stream, guiding the sample into the instrument for analysis. IDEX Health & Science offers injection valves in metal and bioinert (metal-free) options. These valves can be easily integrated into your platform, for all systems ranging from low pressure (7 bar, < 100psi) to ultra-high pressure (1300bar, 18,000psi). Backed by extensive in-house life testing, you can trust us to be your reliable partner for sample injection valves.

Most switching valve solutions can be seamlessly integrated onto a custom manifold. Manifold mounting of switching valves can simplify the flow path and fluid connection points during instrument assembly. The addition of other components to the manifold such as probes, pressure sensors, and solenoid valves can take the most complex flow path and streamline it into one complete fluidic engine.

IDEX Health & Science is committed to helping you get to market quickly. Most valve solutions include complimentary access to our IDEX Health & Science Library. The library helps you save weeks of development time using Python™ programming language to abstract low-level communication protocols and quickly write the methods required to control our valve components.

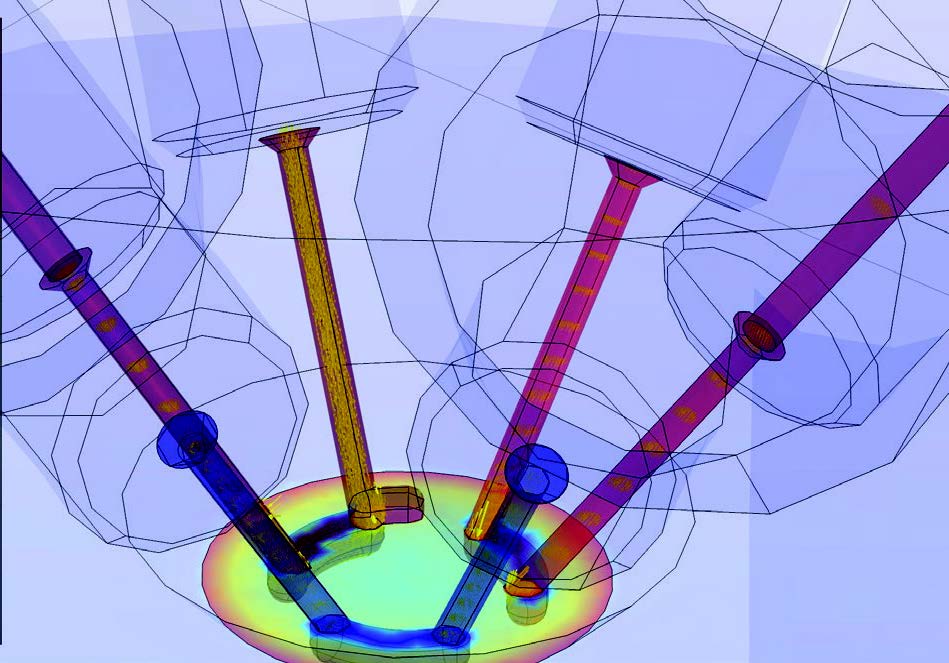

IDEX Health & Science has a team of Engineers and Scientists to support your product development needs. Our technical team deploys many tools including FMEA, CFD, FEA, DFX, Tolerance Analysis, DOE, and Weibull-based lifetime demonstration testing to ensure our valve solution will solve your fluidic challenges.

We partner with your design team, acting as your valve experts and ensuring that the complex geometries of valve components are appropriately prototyped, to reduce the risk of premature lifetime failures or expensive re-iteration cycles. Our RPV program delivers prototypes to you in less than six weeks, so you can start your development testing and get to market faster.

In addition to our off-the-shelf valves, IDEX Health & Science offers customization and support for your fluidic solution.

Whether you are looking to direct magnetic beads across your sample preparation system for automated dilution and filtration, or incorporate dynamic mixing and washing, we can help you direct flow and maintain controlled conditions and fluid volumes to ensure the proper execution of your application.

At IDEX Health & Science we've directed significant focus toward solving sample processing problems for the analytical, biological, and chemical sciences. We are experts in diverse technologies such as flow control, stream switching, flow path multiplexing, and chromatographic separation. Selective incorporation of electromechanical components, such as shear valves and pumps, or passive components like flow restrictors and mixing chambers, are part of the norm in IDEX’s fluid path design; we offer an enormous variety of combinations.

Simplifying the complex. In this demonstration valve, we have created an 8 position, 17 port stream selector. Here the groove pattern allows for flow through adjacent ports (e.g., between ports 2 and 2’) in one position, but as the valve rotates, the flow is redirected (from port 2 to the common out port). This can allow you to sample from multiple streams to perform your specific sample / dispense / wash application.

We are innovators in of optimizing and integrating multiple fluidic components to accomplish reliable assays with high reproducibility. Contact us to find out how we can turn your vision into reality.

Our valves come in a wide range of materials to support your specific needs. When working with biological material such as proteins, DNA, or other metal sensitive components, we offer a wide variety of bioinert metal-free solutions. Our valves are designed for low pressure (< 1 bar / 7 psi) up to ultra high pressure operation (1300 bar / 18,000 psi)

Stainless steel and other metal options are available when bio-inert is not required. Contact us to discuss what material recommendation we have for your specific application.

Valve ports will be compatible with either ¼-28”, 10-32, or 6-40 fittings, depending on the specific valve and needs. Below you will find a variety of reference materials to ensure you make a seal to tubing without delay volumes:

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.