Fluidics

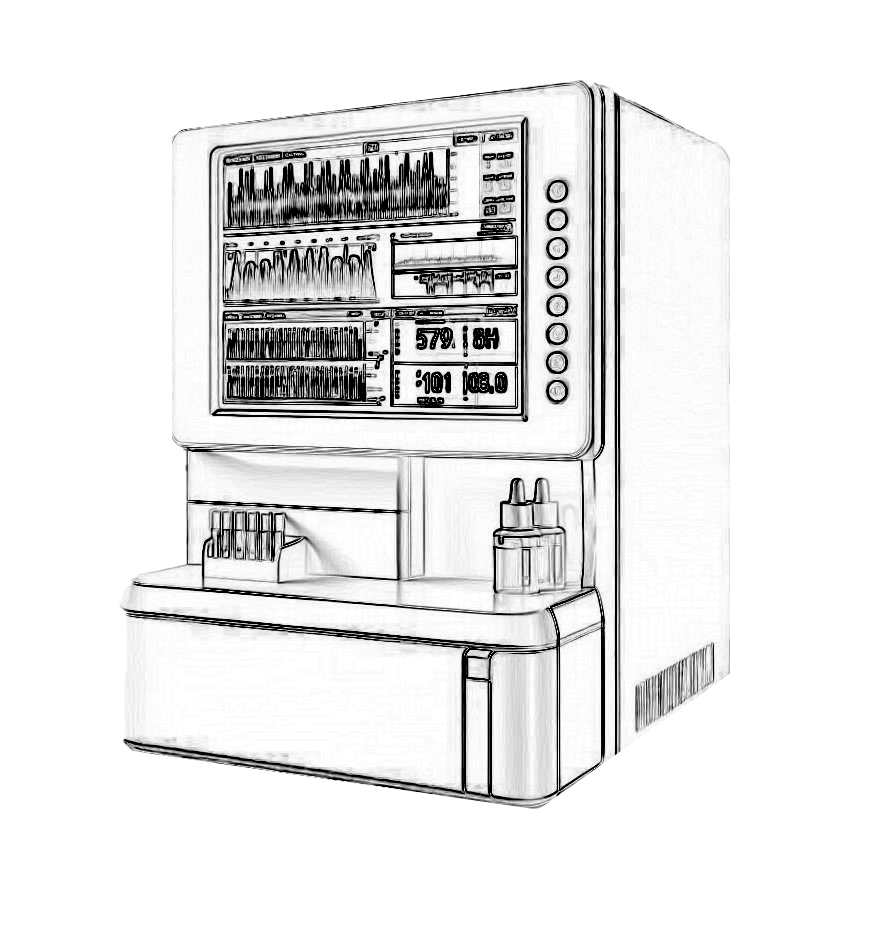

Uptime is paramount for an instrument in a clinical laboratory. IDEX Health & Science designs products for precise fluidic dispense and distribution, giving careful consideration to low cost of ownership, and rigorously testing components for durability, providing you the assurance of maximum instrument quality, consistency, and robustness.

From probe wash manifolds to long-lifetime precision dispense pumps, IDEX Health & Science is your partner for in-vitro diagnostic platform development and production. Whether you looking for design expertise on a custom solution or the manufacture of an in-house design, we can bring your solution to life. Our state-of-the-art CNC machining capabilities provide rapid prototyping, precision production, and automated high throughput capabilities; all components are factory tested, ensuring they meet your specific tolerances with consistent on-time delivery, no matter which stage you are in your project development.

60 years of fluidic engineering expertise and comprehensive performance testing tools are why IDEX Health & Science components are trusted in many commercialized clinical laboratory platforms including immunoassay, hematology, chemistry, microbiology, and urinalysis. Let’s partner to bring your clinical system to life with high-quality sample characterization, maximum uptime, and low total cost of ownership.

IDEX Health & Science specializes in taking complex concepts to reality. We partner with you to remove the risks in controlling reagents, optimizing samples, and designing unique fluidic pathways, turning your theory into a working solution advance your instrument design.

Download our Clinical Laboratory Fluidics Guide

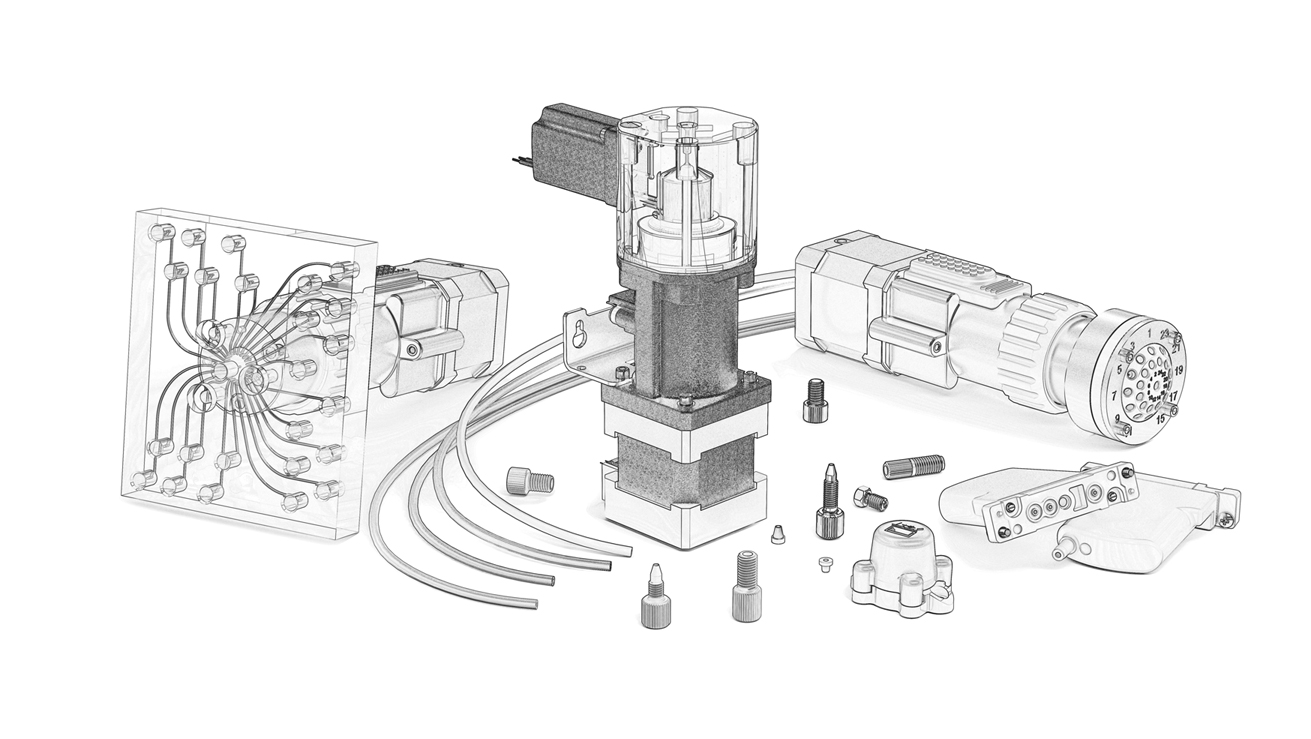

Click the icons below to learn about each of the fluidic components in a Clinical Laboratory instrument.

Whether you are looking for something built to-print or custom-designed, we provide robust, cost conscious solutions for easy instrument operation and serviceability. With milling, turning, cross drilling, 5th axis and multi-layer bonded manifold capabilities, design possibilities are endless. Choose from our wide variety of polymeric materials to ensure the best performance for your platform.

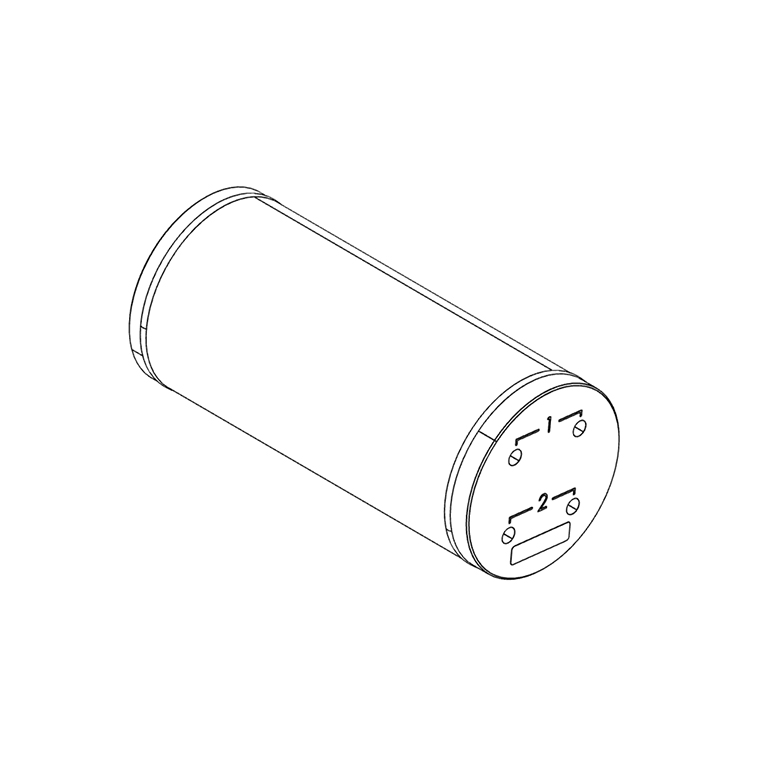

The formation of bubbles in a fluidic line can disrupt the precision and accuracy of instrument dispense and optical detection. Whether introduced through reagent mixing, long idle periods of time, or changes in temperature, outgassing can cause bubble problems that impact instrument read outs. Incorporating a degasser into the stream provides trouble-free operation, ensuring the fluidic system is free of air bubbles. Degassing options for flow rates up to and over 600mL/min are available, with our without a vacuum pump assembly.

Learn More about our Degassing Chamber and Systems Capabilities

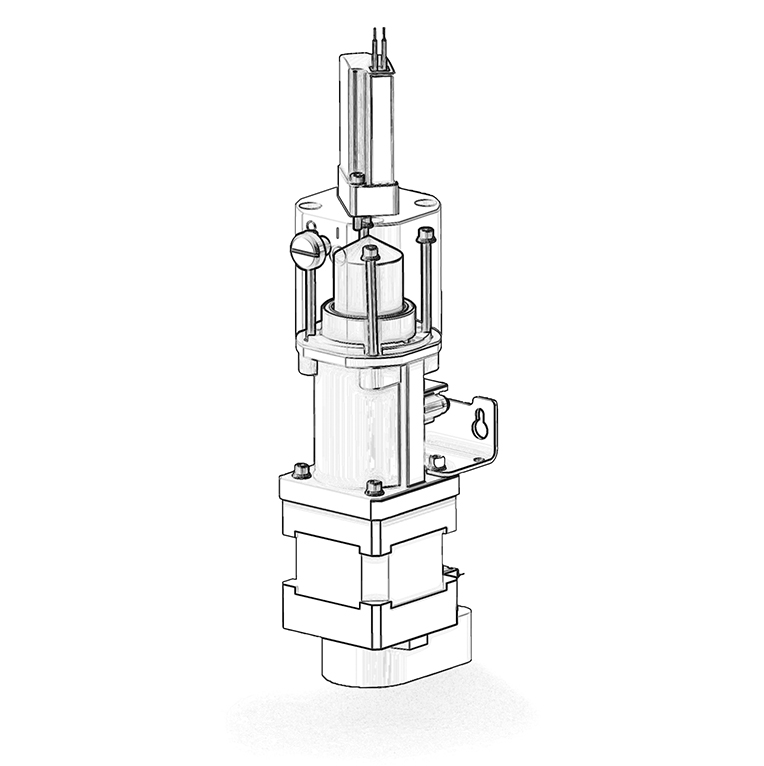

Our long life positive displacement pumps deliver buffers and reagents with a high degree of fidelity for both sample preparation and analysis of your samples. Multiple sealing material options are available to ensure lifetime performance based on your specific pumping requirements, minimizing the need for field service.

Instruments that require the specific introduction of fluids, such as those running HbA1C assays, require a robust, repeatable valve solution. IDEX Health & Science valves are fully biocompatible and cover a wide range of flow, pressure, and reagent distribution solutions. They are offered as standalone components or integrated onto a manifold assembly to meet the specific needs of your unique design.

We offer a comprehensive line of biocompatible tubing and connection options that meet the demanding requirements of today’s high-performance instrumentation. As a manufacturer of tubing and connections, IDEX Health & Science is uniquely positioned to help you integrate your tubing into kits and assemblies for the simplified installation and serviceability of your platform.

With rapid prototyping and high throughout automation capabilities, our site can scale up the production of your manifolds quickly once the design is locked. Individual set-up times will depend on the complexity of the design, but we can often turn around your critical project within a few weeks.

The maximum flow varies based on the size of the pump and the back pressure in the system. While there are many techniques for achieving advanced performance, a general rule is to dispense the entire volume of the pump within two seconds at low pressures (< 100psi). Changing the pump size, resolution, motor configuration or operating parameters are methods for meeting increased pressure or flow needs. Our engineering team can help by recommending a configuration that best achieves the customers desired performance

A general rule is that our inline series can dispense 2% of the selected pumps full volume with a repeatability better than 1% CV. Smaller volumes can be dispensed with less repeatability/p>

For complex bonded manifolds, IDEX typically utilizes PMMA (Acrylic) and PEI (Ultem 1000). PMMA is recommended for systems with inert reagents; PEI is better suited for applications utilizing more aggressive reagents (i.e. solvents). IDEX can offer a wide variety of polymers (e.g., PEEK, PVC , POM, and Polypropylene) for simple, cross drilled manifolds.

Situations such as cold incoming bulk fluids, pressure drops across the system, turbulent flow or onboard dilution can lead to bubble formation due to outgassing. Placing a degasser upstream conditions fluid throughout the instrument to avoid bubbles and maintain precision.