Life Science Optics

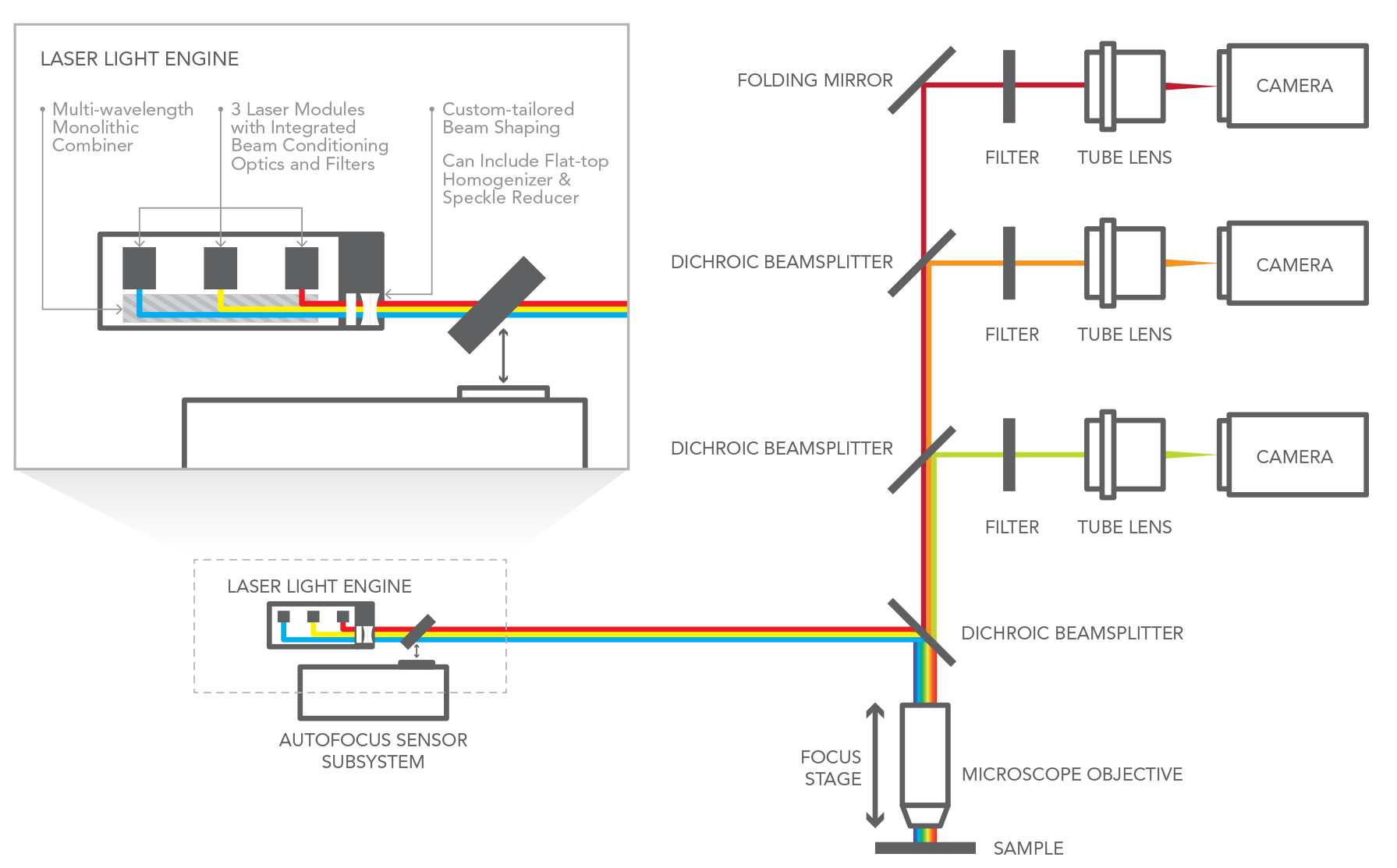

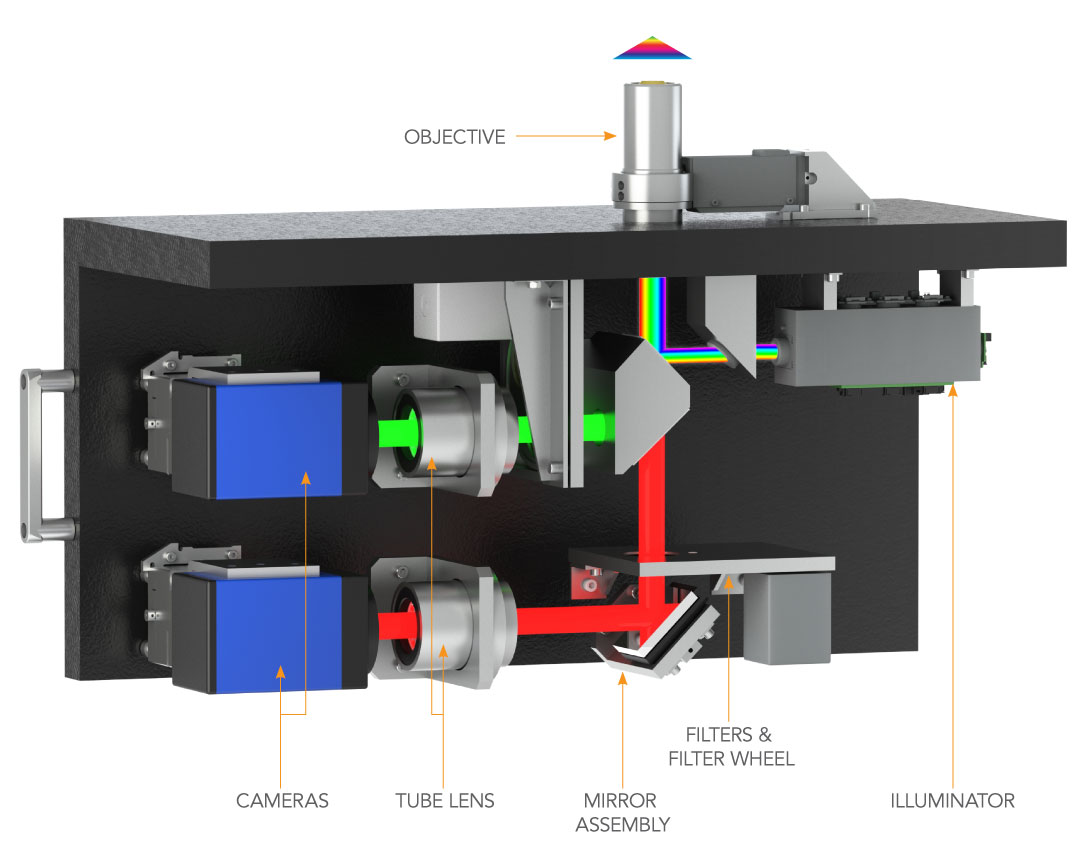

When you need a complete fluorescence microscope-based optical system at the core of your life science or other high-performance instrument, our expertise in all aspects of optics combined with our proven design-through-manufacturing approach is your solution. Systems engineering always requires trade-offs to be made and these decisions have significant consequences in terms of performance, price, and reliability. This maxim is just as true for an optical system — where illumination optics, imaging optics, spectral optics, an autofocus system, a detection system, and all other supporting optical, opto-mechanical, and electronic components required to interface the system to the overall instrument must work flawlessly together time after time. Don’t risk bolting together parts that weren’t designed with one another in mind. Let us design and build a fully integrated system for your instrument.

As experts in illumination delivery systems, we specialize in custom-tailored beam profiles that deliver the precise spot you need at the point of work, dramatically reducing system cost and complexity — and significantly improving system performance. To achieve this high level of precision and repeatability, we have become vertically integrated for close control of the most critical components while minimizing production lead-times. From in-house superpolishing capabilities to dedicated ion-beam sputtering (IBS) thin-film coating chambers for coating intracavity optics, we ensure high-quality critical components for both prototype development and production platforms alike.

We employ multiple lens assembly techniques, from our proprietary “Exact Placement” approach for the most demanding, micron level tolerance systems, to our state-of-the-art “Alignment Turning” capability for cost-effective, high-performance optical assemblies in high volumes. These, combined with the implementation of unique solutions such as magneto-rheological finishing (MRF) post-processing and real-time, interferometrically controlled aberration compensation, ensure outstanding and consistent system-level performance.

Through our innovation, in-depth know-how, and unique set of technical competencies, our designs represent the very best solution for each application. We design and accurately simulate “as-built” complete optical systems, including stray-light analysis and FEA modeling for resonance, thermal, and mechanical stress effects. Coupled with advanced component-through-assembly fabrication experience and system-level thinking, this approach ensures that the end-product has been fully optimized for manufacturability, cost, and performance, that can be directly transitioned to production.

By bringing together expert system design, vertically integrated state-of-the-art manufacturing capabilities, and extensive optical metrology under one roof, we can take on projects at any level of design maturity, and quickly bring them to market. Ultimately, with our long history and customer-centric culture, we provide the solutions you need in order to differentiate and outperform your competition.

Through strategic partnerships, IDEX Health & Science can support the design and development of unique, high-performance, fluorescence microscope-based optical systems that are optimized to meet the ever-increasing performance requirements of life science applications. With our in-house design and manufacturing capabilities, we can develop optimal designs with your whole system in mind from the start.

Check out our case study about a next-generation fluorescence-based life science instrument: