Fluidics

We understand how difficult it is to design an instrument for the rapid evaluation of cells under increasingly demanding conditions. In order to provide researchers with reliable results, instrument fluidics must offer precise performance. With cutting-edge technology and a team of dedicated experts, IDEX Health & Science is committed to unlocking the full potential of your flow cytometer.

Our high-performance sheath pumps and low-dispersion valves efficiently guide the sample to the optics. Benefit from the integration of pressure sensors and a degasser in the fluidic path to maintain instrument uptime, ideal sample delivery, and efficient cell focusing and sorting. Partnering with IDEX Health & Science on your instrument design enables you to develop your optimal fluidic system.

IDEX Health & Science specializes in taking complex concepts to reality. We partner with you to remove the risks in controlling reagents, optimizing samples, and designing fluidic pathways, turning your theory into a working solution that advances science.

Download our Flow Cytometer Fluidics Guide

Click the icons below to learn about each of the fluidic components in a flow cytometer

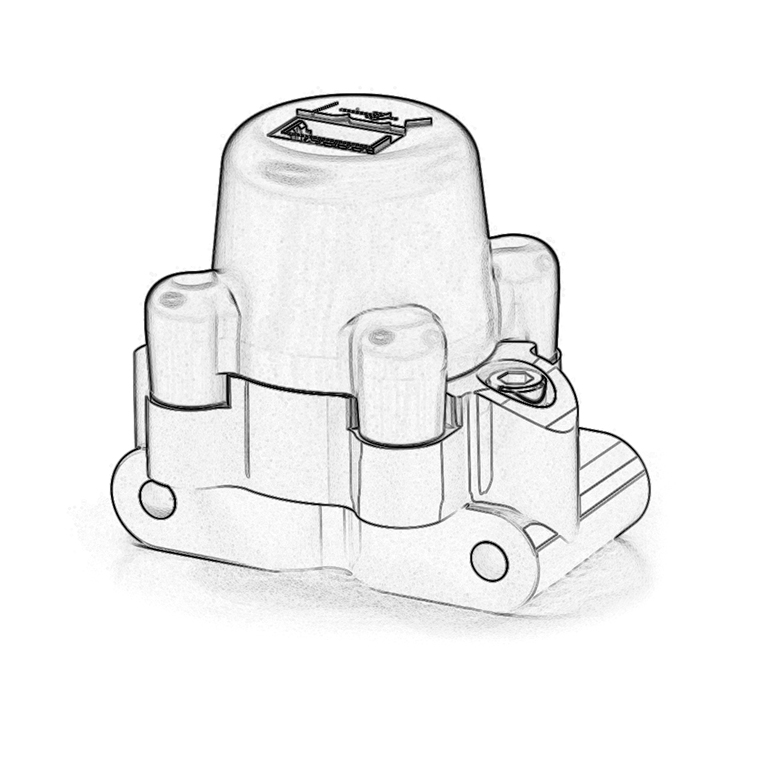

Streamline your flow path with our precise distribution valves. A fully customizable fluid path provides the flexibility to design for number of ports, cost and optimal sample introduction needs. With negligible reagent crossover concern and low internal volume, our valves allow you to expertly control sample streams, supply sheath fluid, and introduce cleaners into the stream. Valves can be offered as standalone or integrated into a manifold assembly to meet the needs of your unique design.

Inline pressure sensors can monitor system performance, providing alerts to flow anomalies and ensuring proper performance of demanding operations, such as hydrodynamic focusing. The extremely low internal volume, negligible pressure compliance, and digital communication of our sensor provide simplicity for your flow control.

The presence of bubbles in a fluidic line can disrupt the precision and accuracy of your system. Incorporating a degasser into the stream provides trouble-free operation that ensures the fluidic system is free of air bubbles by actively removing dissolved gases. IDEX Health & Science inline degassing chambers provide superior fluid conditioning, improving instrument precision and assay quality.

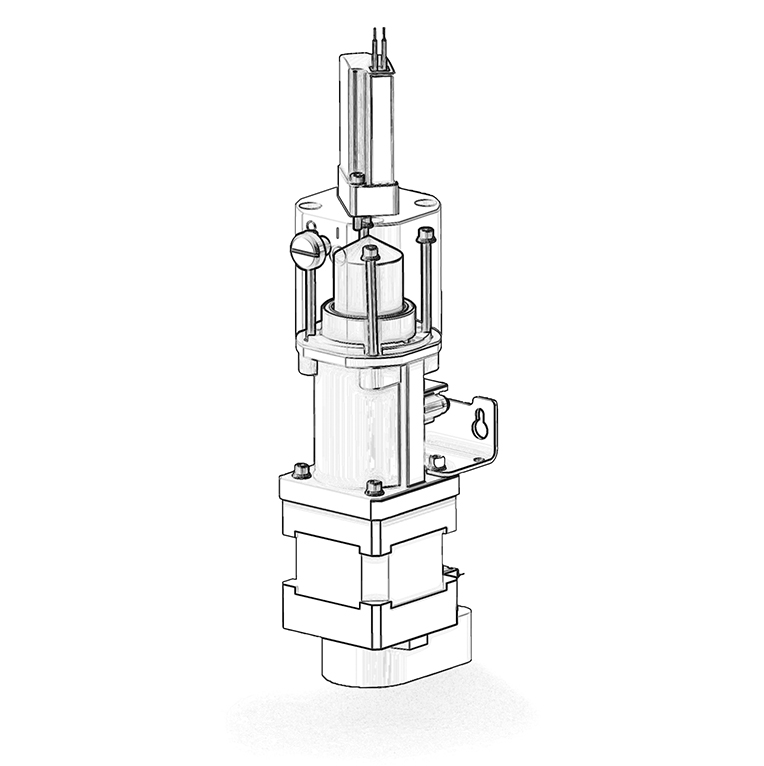

Our positive displacement pumps deliver buffers and reagents with a high degree of fidelity. Our long life pumps ensure consistent sheath and sample flow rates under diverse conditions. An ultra-smooth ceramic piston with precise tolerances lowers dynamic friction delivering excellent flow stability and gentle handling of sensitive samples.

We offer a comprehensive line of custom tubing options that meet the increasingly demanding requirements of today’s high-performance analytical fluidic systems. We are the premier provider of intelligently engineered fluidic assemblies providing instrument developers simplified installation and serviceability of their complex fluidics.

We have a team of engineers specialized in fluidic design and application work, they can help guide you through the process.

Our team of engineers can computationally model to ensure the design is sound. Saving you valuable time prototyping, getting you to market faster, and identifying risk areas early in the development process.

Pressure monitoring is key for flow control as well as diagnostic evaluation of flow path stability. Our small format pressure sensors are designed to be easily integrated into your instrument for accurate pressure measurements along the stream.

When a reagent undergoes a pressure change, there is a risk of outgassing. Additionally, temperature changes and/or mixing of reagents can cause gas bubble formation in the fluidic stream. Bubbles can introduce flow rate variation and disrupt optical detection. Integrating an active degasser into the fluidic channel prevents risk for error due to dissolved gases.

Our valves, pumps, and tubing assemblies are offered in a wide variety of materials to ensure compatibility for reagents and beads, without the fear of unwanted secondary interactions, or impacting light sensitive compounds.

Using a piston pump provides a smaller instrument form factor by removing the pneumatic system. Additionally, piston pumps simplify the system design, offer better control options than pressurized systems, remove the potential for gas oversaturation, and improve system uptime.

With high-performance flow cytometers moving toward multiple lasers and numerous of detection channels at both visible and near-IR wavelengths, having the right optical filters is essential for complete discrimination of fluorophores. Learn more