Life Science Optics

Finding it difficult to select the appropriate microscope objective lens for your application? Observing imaging errors at the edges of your field of view or intolerable chromatic aberration? Can’t precisely quantify or model the performance of available off-the-shelf objectives? Stop compromising! We are happy to work with you to provide a cost-competitive custom microscope objective solution that is ideally suited to your specific application. We guarantee superior imaging performance and repeatability in volume production.

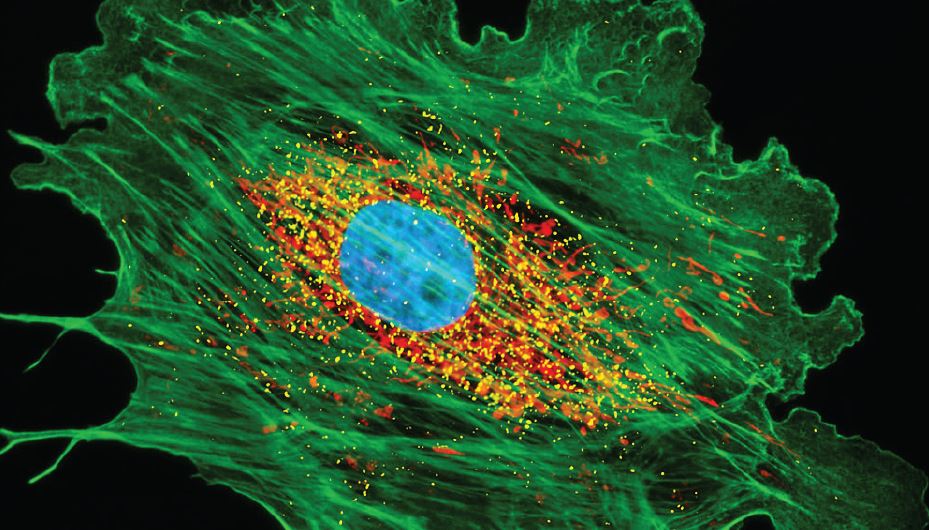

Melles Griot, now a part of IDEX Health & Science has over forty years of experience developing and manufacturing fully customized high-performance optical systems. We have crafted optimal solutions for the most demanding applications ranging from semiconductor inspection and metrology to high-throughput subcellular imaging in life science and medical instrumentation. We routinely produce high-NA, diffraction-limited objectives from the ultraviolet to the infrared. By working closely with your team throughout the full development process—from concept to launch—we enable you to realize a competitive advantage resulting from accelerated time to market, competitive cost, highest quality, and ultimately better product performance.

Most microscope objective lenses available and in use today were not designed for a specific application. They are generally optimized for best performance at the center of the field of view (FOV), and color correction is either limited or enhanced over a broad wavelength range in the most expensive objectives. And they are generally not manufactured to meet today’s demanding instrument repeatability requirements.

By choosing a IDEX Health & Science custom objective lens solution, you will experience:

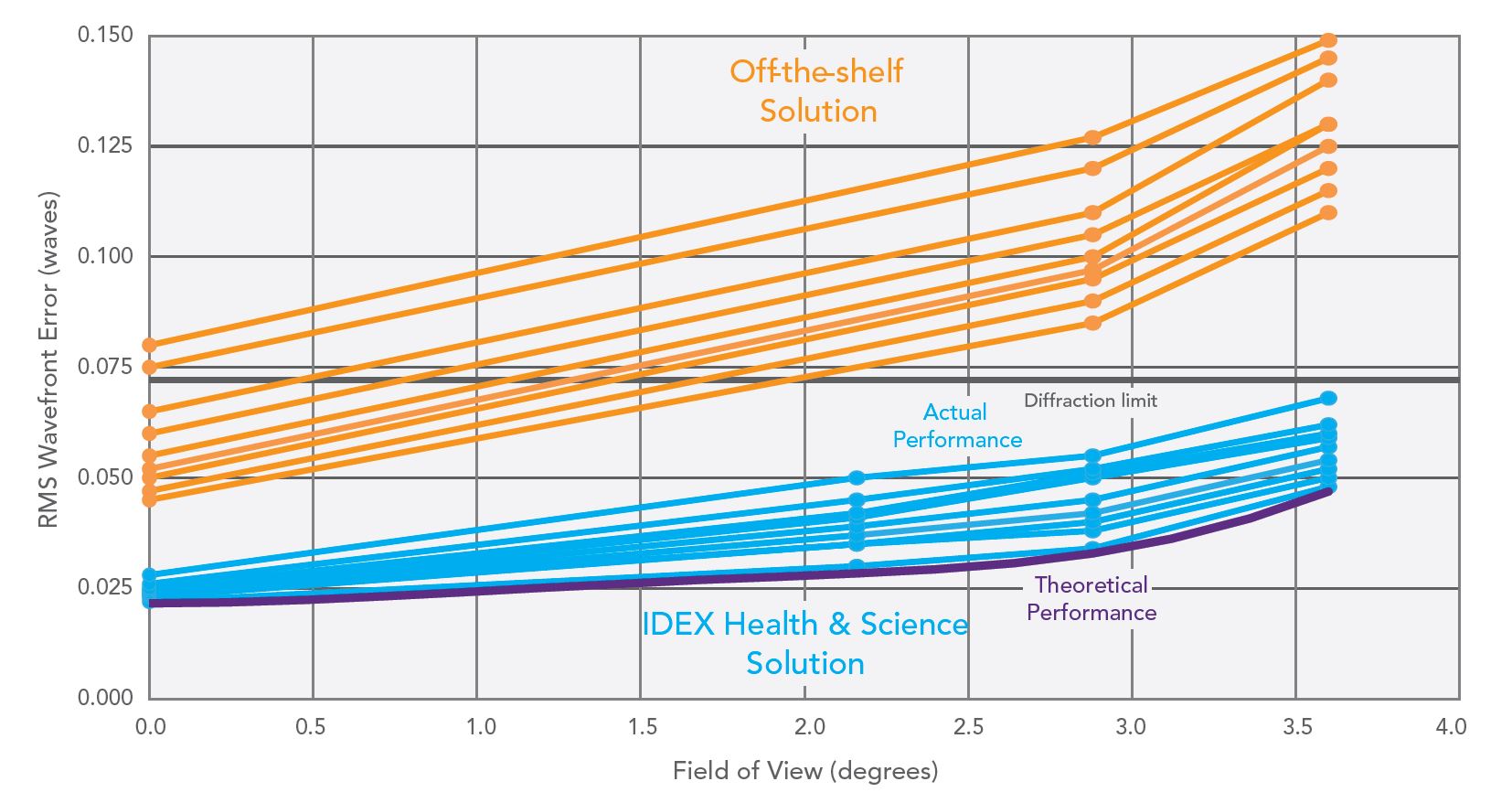

The current generation of one OEM customer’s instrument was based on a commercial high-performance 20X / 0.75NA PlanApochromat objective. But this objective could not satisfy the next-generation instrument requirements due to insufficient resolution and color correction over the full FOV, as well as high variability, spatial distortion, and thermal sensitivity (see orange data in graph below).

IDEX Health & Science custom-tailored solutions offer superior wavefront correction over the whole imaging field.

Our team collaborated closely with this customer’s development team to create a unique objective solution, complete with custom tube lens. This solution achieves diffraction-limited, vignetting-free and extra low-distortion performance over two broad wavelength bands, a wide temperature range, and the entire FOV. And because it was designed specifically for our vertically integrated, volume manufacturing capabilities, this performance is obtained with high yield and guaranteed with extensive testing. The result: the customer’s next-generation instrument is able to meet all of their target market requirements for higher accuracy, throughput, and reliability.

By specifically addressing each of your application’s requirements, our custom objective designs create differentiation that ultimately reduces your overall system complexity while significantly improving performance compared to off-the-shelf objective solutions.

Looking for the right partner to realize your next project? We have routinely taken the most challenging projects successfully from concept to volume production and are ready and eager to take on yours.

Application Knowledge and Collaborative Development Process: Whether you are developing a semiconductor metrology tool or life science imaging instrument, our engineers have extensive application-specific design expertise and work closely with your team to define the criteria that are most relevant for your application. The results are optimized trade-offs among competing specifications and balanced performance versus cost. We are recognized for our interactive and open design philosophy—we work intimately with our customers through every stage of the project, and provide full access to design details.

Superior wavefront capability with magneto-rheological finishing (MRF®)

Engineering Excellence: Through our innovation, in-depth know-how, and unique set of technical competencies, our designs represent the very best solution for each application. We design and accurately simulate “as-built” optomechanical imaging systems, including stray-light and FEA thermal and mechanical stress analyses. Coupled with advanced component-through-assembly fabrication experience and system-level thinking, this approach ensures that the end-product is fully optimized for manufacturability, cost, and performance, and can be directly transitioned to production.

The Most Advanced and Innovative Technologies: IDEX Health & Science employs multiple lens assembly techniques, from our proprietary “Exact Placement” approach for the most demanding, sub-micron tolerance systems, to our new, state-of-the-art “Alignment Turning” capability for cost-effective high-performance assemblies in higher volumes. These, combined with the implementation of unique solutions such as magneto-rheological finishing (MRF) post-processing and real-time, interferometrically controlled aberration compensation, ensure outstanding and consistent system-level performance.

High capacity and precision is achieved with state-of-the-art alignment turning technology (photo courtesy of TRIOPTICS GmbH)

Unequaled repeatability and scalability result from integrated metrology in the ATS 200 alignment turning machine (photo courtesy of TRIOPTICS GmbH)

Extensive System Verification and Testing: A customized Acceptance Test Procedure (ATP) is developed for each product, with testing performed at functional wavelengths to ensure performance in the final application.

Complete Optical Solutions: By bringing together expert system design, vertically integrated state-of-the-art manufacturing capabilities, and extensive optical metrology under one roof, we can take on projects at any level of design maturity, and quickly bring them to market.

The following table lists some examples of custom high-performance objectives we have recently designed, developed, and delivered for our customers’ production. Let us craft the most optimal solution for your application.

| Numerical Aperture | Immersion Medium | Wavelength Range | Specimen FOV (mm) | Working Distance (mm) |

| 0.500 | Air | 530 - 750 | 3.20 | 3.20 |

| 0.750 | Air | 480 - 650 | 1.20 | 1.20 |

| 0.900 | Air | 545 - 770 | 0.46 | 0.46 |

| 0.900 | Air | 680 - 950 | 0.46 | 0.46 |

| 0.900 | Air | 470 - 650 | 1.10 | 1.10 |

| 0.950 | Solid | 780 - 790 | 0.19 | 0.19 |

| 0.950 | Solid | 950 - 2000 | 0.20 | 0.20 |

| 0.950 | Solid | 574 - 580 | 0.20 | 0.20 |

| 0.950 | Solid | 1050 - 1600 | 0.21 | 0.21 |

| 0.825 | Water | 505 - 705 | 1.10 | 1.10 |

| 0.825 | Water | 505 - 820 | 1.10 | 1.10 |

| 1.100 | Water | 505 - 820 | 0.72 | 0.72 |

Download Custom Microscope Objective Data Sheet