IDEX Health & Science: Your Partner for High-Performance Optical Systems

Melles Griot® Optical Systems from IDEX Health & Science lead as the premier innovator, designer, and manufacturer of high-precision optical systems for fluorescence microscope-based applications such as Next-generation Sequencing (NGS), Spatial Biology, Next-generation Proteomics (NGP), and Flow Cytometry. Empowering OEM life science companies, we enable the development of cutting-edge high throughput, high resolution imaging instruments, pushing the boundaries of discovery and clinical applications. With a fully integrated approach, we cover the entire optical design and manufacturing processes, offering custom and semi-custom solutions that cater to every phase of the instrument development needs, from proof-of-concept breadboards to volume production. Our extensive portfolio encompasses the full spectrum of fluorescence microscope systems, including illumination systems, autofocus systems, objective lenses and tube lenses, as well as filters and cameras.

- Our team brings over 100 Years of experience

- 300+ total employees

- Including 160+ Engineers who drive innovation

- Our teams have been awarded ~200 Patents

- 115,000 sqft manufacturing center

- Including 30% clean room space

- $100M+ total infrastructure investment

- High-performance purpose-built Imaging components and modules (objective tube lens, imaging subsystems) shipped in quantities of 100s to 1000s per year

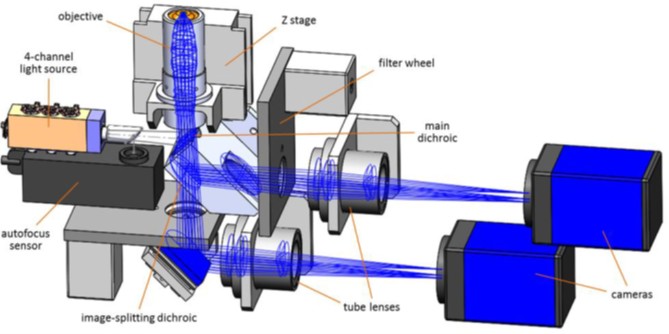

All components of a fluorescence microscope system have to work in harmony in order to maximize data throughput. We understand that architecture decisions of every element within a system impact overall performance, which is why our team of experts works with you along every step of your design. Collaboratively, we create a seamless solution to suit your instrument’s specific requirements, balancing performance, cost, and timeline.

Our success stems from a unique combination of deep technical knowledge, life science industry domain expertise, and a customer-centric cooperative approach that provides seamless design and integration for your system. Working with harmonized components, designed to optimize your system's resolution and throughput requirements, helps avoid costly delays and inconsistent quality.

Customer Challenges: The Problem IDEX Health & Science: Your Solution

Holistic Product Development for Optimal Results Supply Chain Excellence

Customer Challenges: The Problem

- Developing a high-performance, high data throughput fluorescence microscope that increases the pressure on resolution and throughput is challenging.

- Optical designers are confronted with weighing the pros and cons of various system architecture options while juggling budget limitations, component availability, and tight product release schedules to achieve desired outcomes.

- Customers facing limited in-house optical modeling capabilities grapple with trial and error by using off-the-shelf components, leading to costly delays, low confidence in repeatability, and sub-optimal performance. Additionally, seeking consultants can be both expensive and time-consuming.

- Manufacturability is critical in post-design completion to ensure successful commercial product releases. Key challenges include ensuring consistent quality, on-time delivery, and achieving rapid capacity scale-up.

- With material constraints and lead-time uncertainties, the supply chain faces consistent and significant challenges to ensure continuity of supply to meet demand.

IDEX Health & Science: Your Solution

Partner with us to develop unique, high-performance optical systems tailored to your specific needs. With over half a century of high-quality, high-performance optical design and manufacturing legacy, we support multiple high-growth, cutting-edge life science applications in Next-generation Sequencing (NGS), Spatial Biology, and Next-generation Proteomics (NGP). Our team has designed and delivered thousands of purpose-built imaging, illumination, and focus tracking subsystems for Life Science applications, enabling the highest throughput and finest resolutions using high NA, large FOV imaging, and flat-top illumination technologies.

Purpose-built solutions matching every need of the customer product development journey:

- Breadboarding, prototypes, pilots, and production.

- Components, modules or source to sensor subsystems: these include objective and tube-lenses, filters, and sensors, multi-wavelength illumination modules, Imaging modules, Autofocus systems, or full source to sensor subsystems.

- Start-ups with limited in-house optical resources or established companies.

- DIYers or fully outsourced source-to-sensor sub-systems.

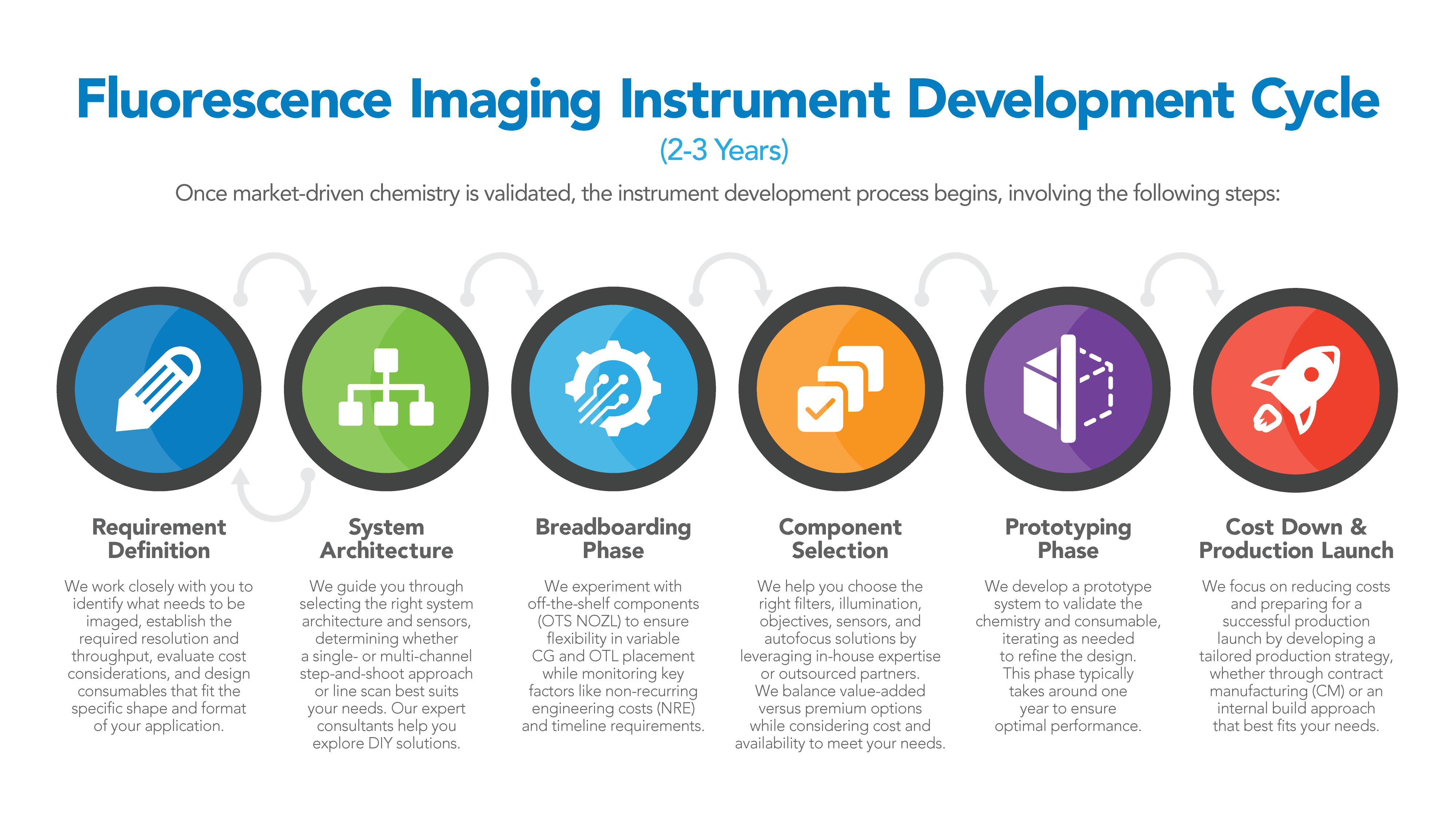

Example of our Fluorescence Imaging Instrument Development Cycle

Engineering Collaborations

Partnering with IDEX Health & Science means collaborating directly with our engineering team. You can expect hands-on attention to detail for all your instrumentation needs including:

- Pre-project design consultations readily accessible within hours and days of initial inquiry.

- Weekly project meetings to share progress, data, optimal design choices, trade-offs, and risk mitigations.

- Detailed DVT/EVT reports and open black-box model data sharing.

- Detailed test reports with every component and subsystem delivered.

- Rigorous yet flexible phase gate-based product development process ensures quality, consistency, and high-yield manufacturability.

We Speak Engineer

Work directly with our engineering team to find customized solutions for your life science instrumentation needs. Learn More.

Example of our Product Development Process

Design for Excellence

Our team of experts will craft innovative solutions that:

At IDEX Health & Science, we prioritize synergy between design and manufacturing. By merging innovative design concepts with efficient manufacturing processes, companies can streamline production, reduce costs, and deliver high-quality products that meet customer demands. By incorporating a Design for Excellence (DfX) principle into the entire product lifecycle, we can significantly reduce costs, accelerate time to market, minimize risks, enhance quality, improve testability, increase production yields, boost customer satisfaction, and optimize operational efficiencies.

- Flexible and Efficient Design Iterations: Facilitate a collaborative design process that allows for efficient refinement and ensures that optimal system architecture choices maximize system performance.

- Balance Cost and Performance: Delivering exceptional value without compromising functionality.

- Rigorous Documentation: Meticulously documented processes and revisions ensure clear communication and project consistency.

- Meet Development Timelines: Our efficient design and manufacturing processes enable your product to market faster.

- Exceed Expectations: Experience superior performance that surpasses industry standards.

Core Technology Capabilities

- Maximized Imaging Throughput: Realize larger field of views (FOV) than off-the-shelf optics, with no vignetting for unmatched image and data quality and significant data throughput improvements.

- High Numerical Aperture (NA) Objective and Tube Lenses: Air and water immersion lenses enable sub-cellular resolutions for the most demanding imaging applications.

- Flat Field Multi-Wavelength Epi-Illumination: Match the large field of view and power for throughput.

- Beam Shaping: Match rapid 2D step-and-shoot imaging and TDI Sensor-based rapid line scan imaging.

- Rapid Autofocus Tracking Modules: Keeps the image in focus during high throughput imaging applications.

- Flexible, Integrated Solutions: Delivering powerful functionality to meet every instrument’s unique requirements.

Holistic Product Development for Optimal Results

Our in-house design and manufacturing capabilities allow for complete system optimization from the very beginning. We possess exceptional expertise in system assembly and alignment, ensuring consistent product quality, peak performance, and support fast production ramp up from pilot to volume within 3 months.

System Optimization Through Every Stage

- Component Innovation: We drive illumination, imaging, and filter design advancements to create industry-leading technologies.

- Solution Customization: Leverage our expertise to tailor systems to your specific application requirements and instrument integration strategy.

- Seamless Systems Cohesion: Our collaborative approach ensures all components are optimized to work together in perfect harmony.

- Rigorous Verification & Validation: Every system undergoes thorough testing to meet your predetermined qualification plan. Guarantee product quality and durability while reducing downtime and maintenance costs. These standard operating procedures contribute to a more efficient, reliable, and cost-effective supply chain.

Customer Case Studies

Supply Chain Excellence

IDEX Health & Science prioritizes supply chain management to ensure on-time delivery and continuity of supply. We mitigate potential risks with our disciplined standard operating procedures and an extensive supply chain network:

- Providing a One-Stop Shop: We simplify your supply chain complexity by identifying cost-effective solutions without sacrificing performance. This is achieved by both sourcing in-house and through our global partner network, in addition to leveraging IDEX Corporation’s economy of scale purchasing power.

- Ensure Continuity Supply: We mitigate supply chain risks through alternative suppliers and backup manufacturing sites, providing redundancy and continuity in case of disruptions.

- Lead Time Management: Our sophisticated tools maintain optimal inventory levels, with detailed product histories to ensure complete transparency, and guarantee timely delivery.

- Faster Time-to-Market: Our internal and extensive parent network enables your product to market sooner with consistent quality and predictable delivery and scale.

Investing in Your Success

Our scalable solutions are designed to accommodate your growing business needs. We prioritize regulatory compliance, ensuring that your product meets all relevant industry standards, including RoHS and REACH. To minimize risk, we conduct thorough product fulfillment risk and failure analysis, proactively identifying and addressing potential issues before they become problems. Our state-of-the-art clean-room manufacturing facilities guarantee consistent product quality, ensuring that your products meet the highest standards.

By partnering with us, you can be confident that your products will be manufactured in a controlled environment, adhering to strict regulations, and delivered on time. Our commitment to quality, reliability, and compliance makes us the ideal partner for your business.

Partner with IDEX Health & Science and unlock the full potential of your life science instruments.

Contact us today to discuss your specific needs and explore how our custom optical systems can propel your research and development endeavors.

*Required Field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.