Fluidics

Challenged with minimizing expensive reagent volumes while maintaining a cost effective, reliable platform? IDEX Health & Science integrated fluidic subsystems provide unmatched system performance. Our superior design expertise enables instrument developers a reduction in fluidic complexity. We have designed and manufactured integrated valve manifold assemblies for years, guiding the fluidics of numerous on market life science platforms. Through vertical integration, our subsystem solutions mitigate risk to performance and minimize cost.

IDEX Health & Science integrated subsystems provide:

Partner with us for your next custom manifold assembly project.

*Required Field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.

As you move from a prototyping to full production, our quality guarantee ensures all your systems will have consistent fluidic performance, tested to your specification.

Below are some examples of how you can harness the power of a manifold assembly. Capabilities can be mixed and matched as needed, and can acts as a starting place for our partnership discussions.

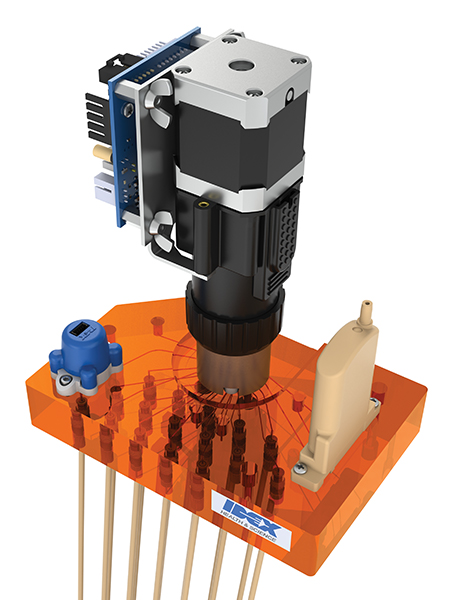

Reagent Selection

![]()

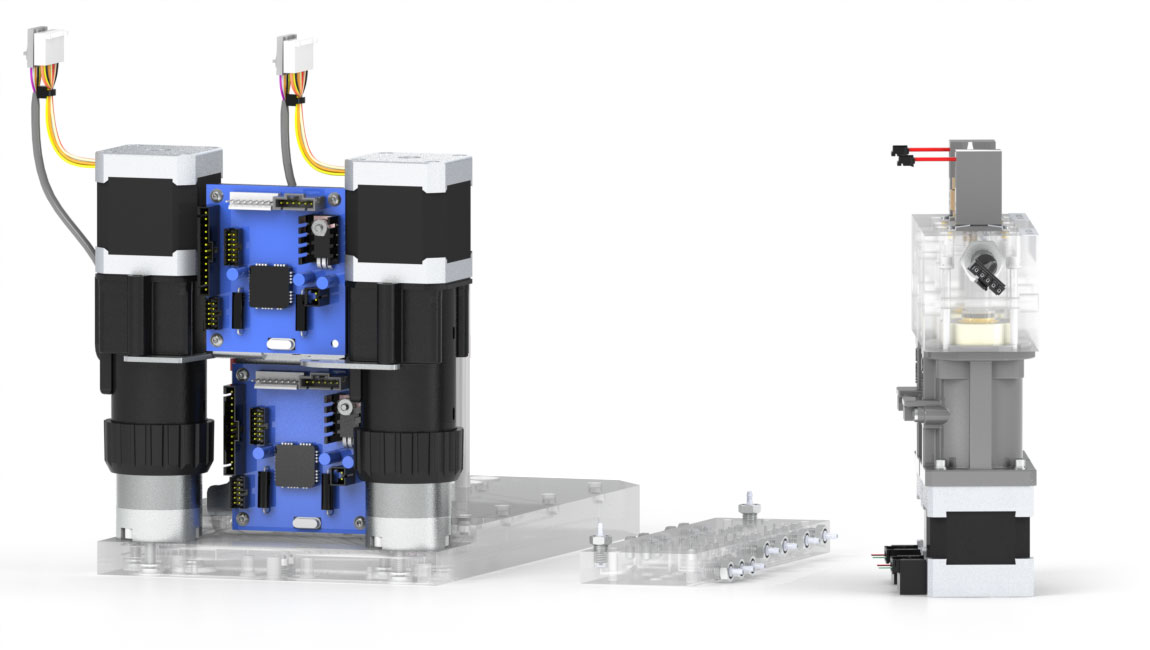

Reagent Preparation

![]()

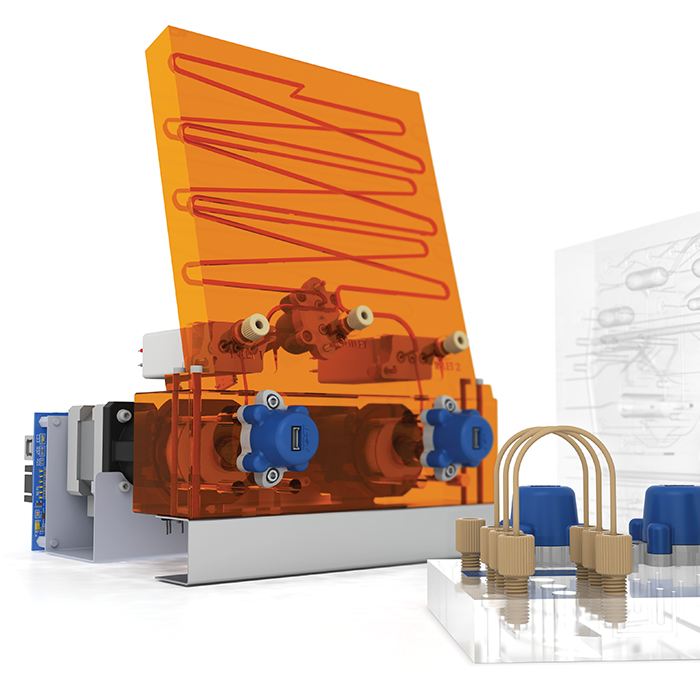

Reagent Routing

![]()

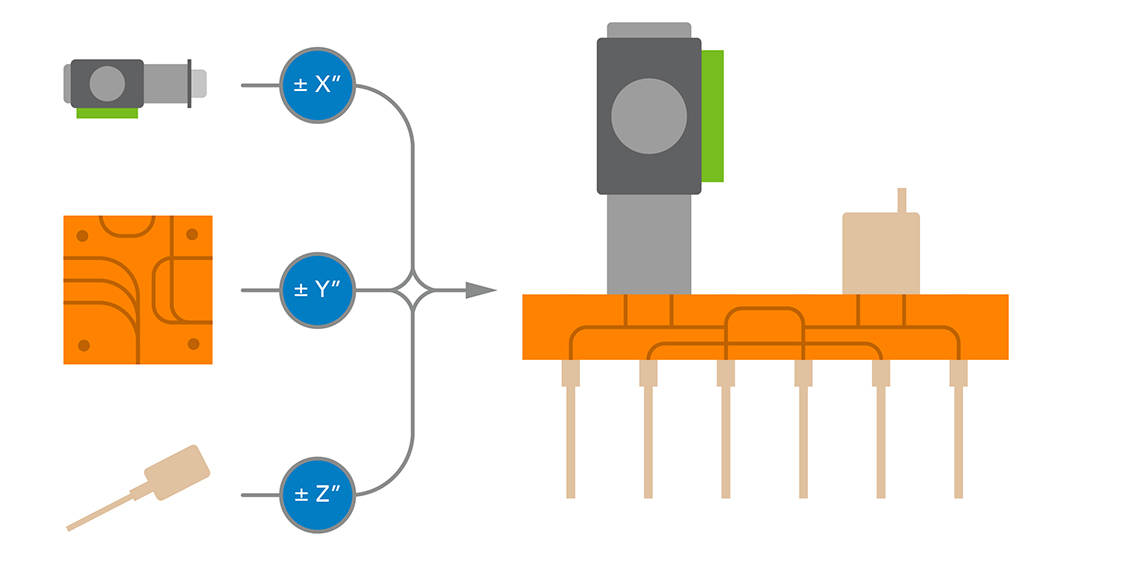

Fluidic Control

![]()

An instrument delivers more than the sum of its parts; this adage is also true for tolerances in design. Manifolds, tubing, fittings, valves, sensors, and degassers each have an inherent manufacturing tolerance. When combined in an instrument, the tolerance stack can be so great that the instrument suffers from significant variability in channel volume and back pressure.

At IDEX Health & Science we test beyond simple fluidic function, we test for a range of fluidic performance to ensure your assay will perform optimally. Testing includes, but is not limited to pressure decay, flow occlusions, pressure drop and mechanical actuation and tolerances of all integrated components. Contact us to learn more about how we ensure your instrument performance.

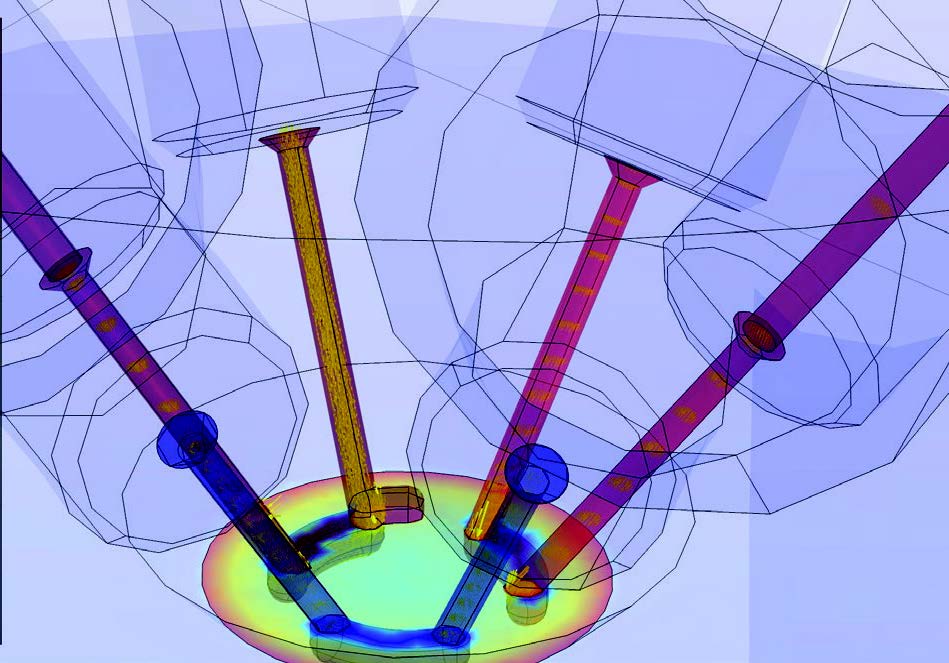

Modeling fluidic flow is essential when considering development costs and time to market. Without a preemptive and proactive fluidic analysis, the product development approach may run into several errors and unforeseen complications. Using computational fluid dynamic modeling, IDEX Health & Science offers instrument developers an option to analyze how their fluidics will operate before committing to expensive prototypes.

Through conception and prototyping to final production stages, we solve complex problems with you to advance your vision. We seamlessly bring your complex instrument designs to life through IDEXology and agile engineering, allowing you to design tomorrow’s technology today. Our more complex fluidic subsystems will include a dedicated Project Manager to ensure your project gets to market on time, with high quality and cost control.

IDEX Health & Science ensures the quality of both new and existing product designs using Statistical Quality Control (SQC) methods to monitor our processes. We are committed to providing top-quality components and subassemblies. Our Operational Excellence includes six sigma, 5S and Lean Manufacturing Techniques. With routine audits and Continuous Improvement efforts we are committed to always delivering you a quality product.

“People choose IDEX Health & Science for their engineering expertise and high-quality manufacturing.” -Sr. Program Manager, emerging biotechnology company