Drive Fluid Across Many Applications with a Manifold Assembly

What is a Manifold Assembly?

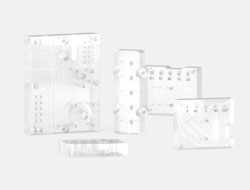

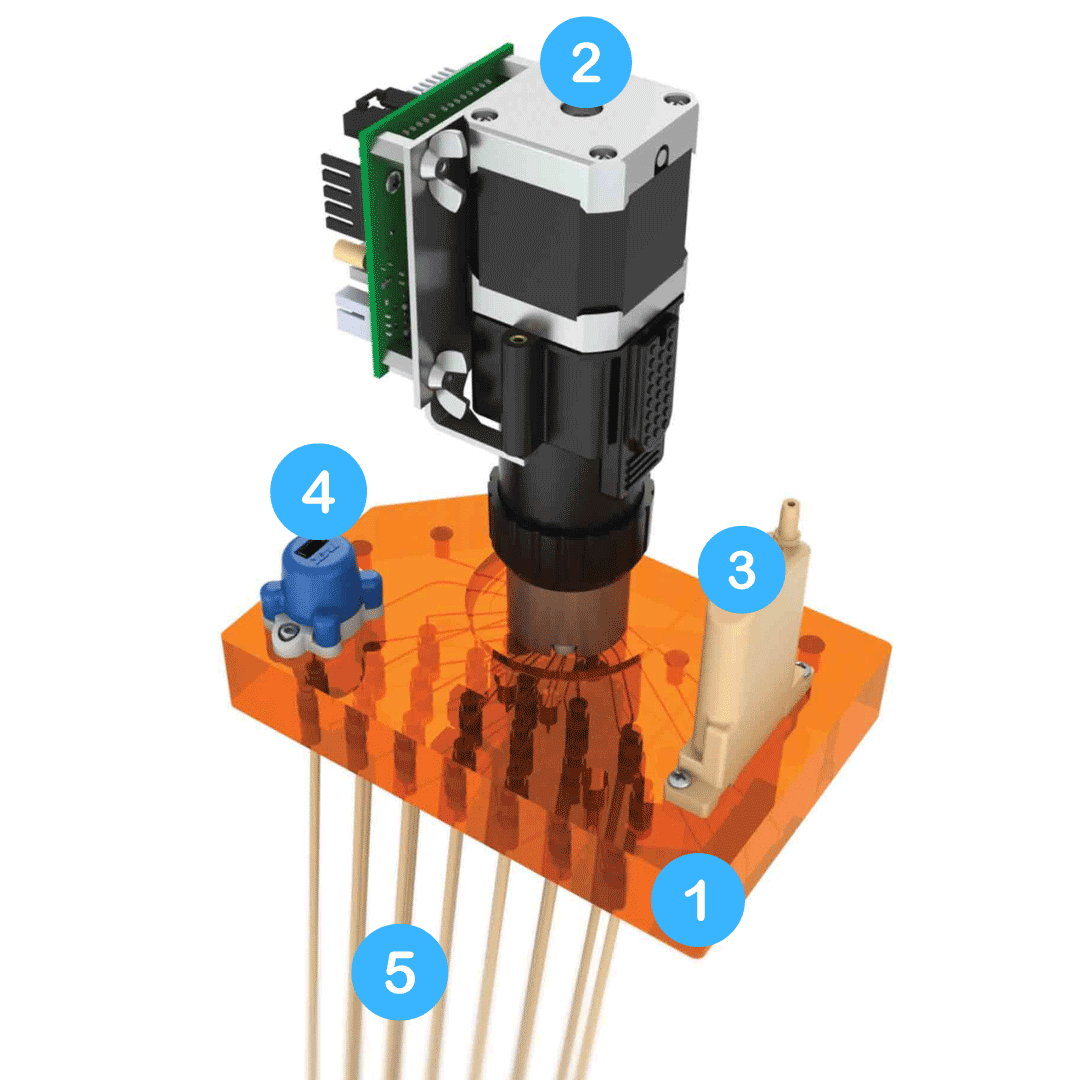

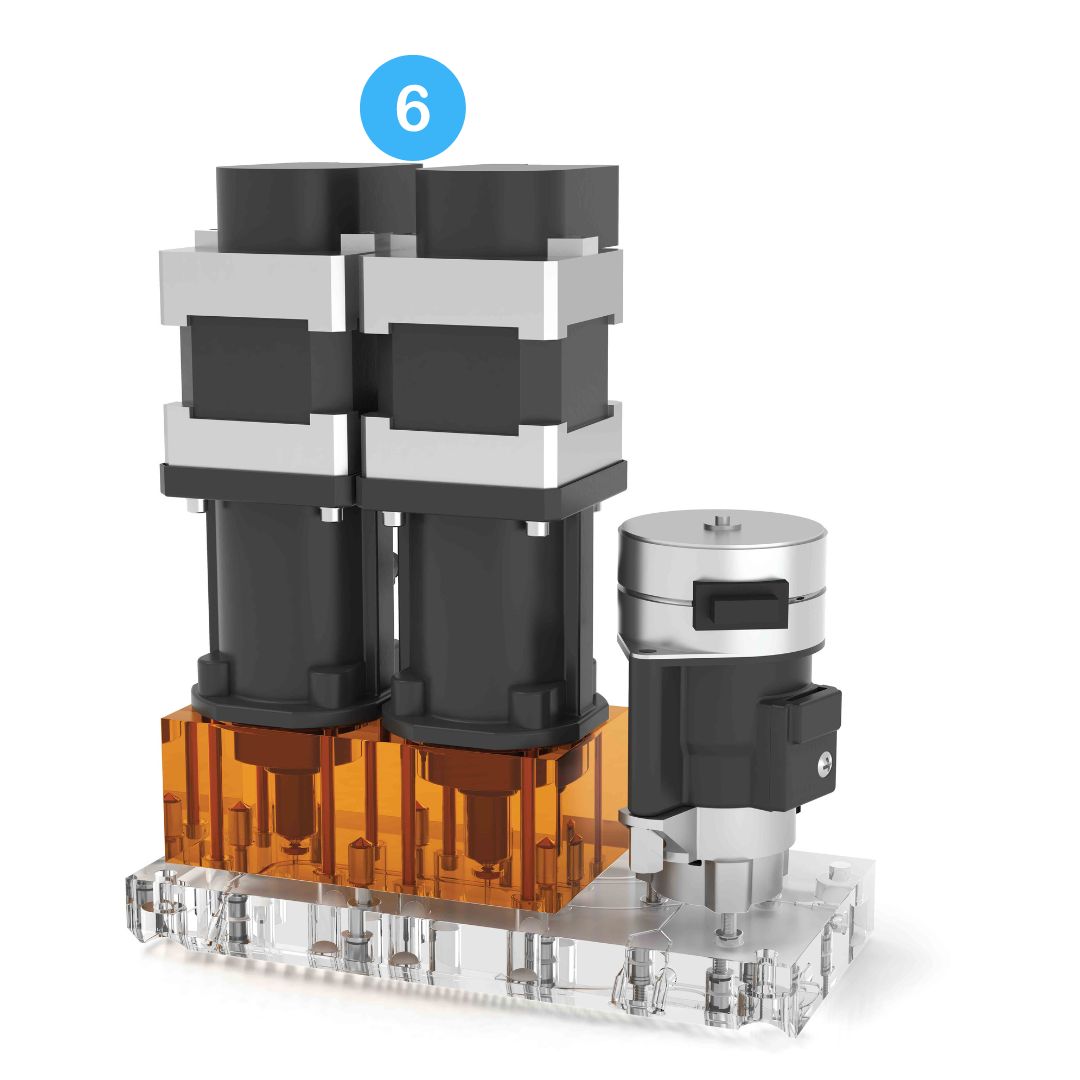

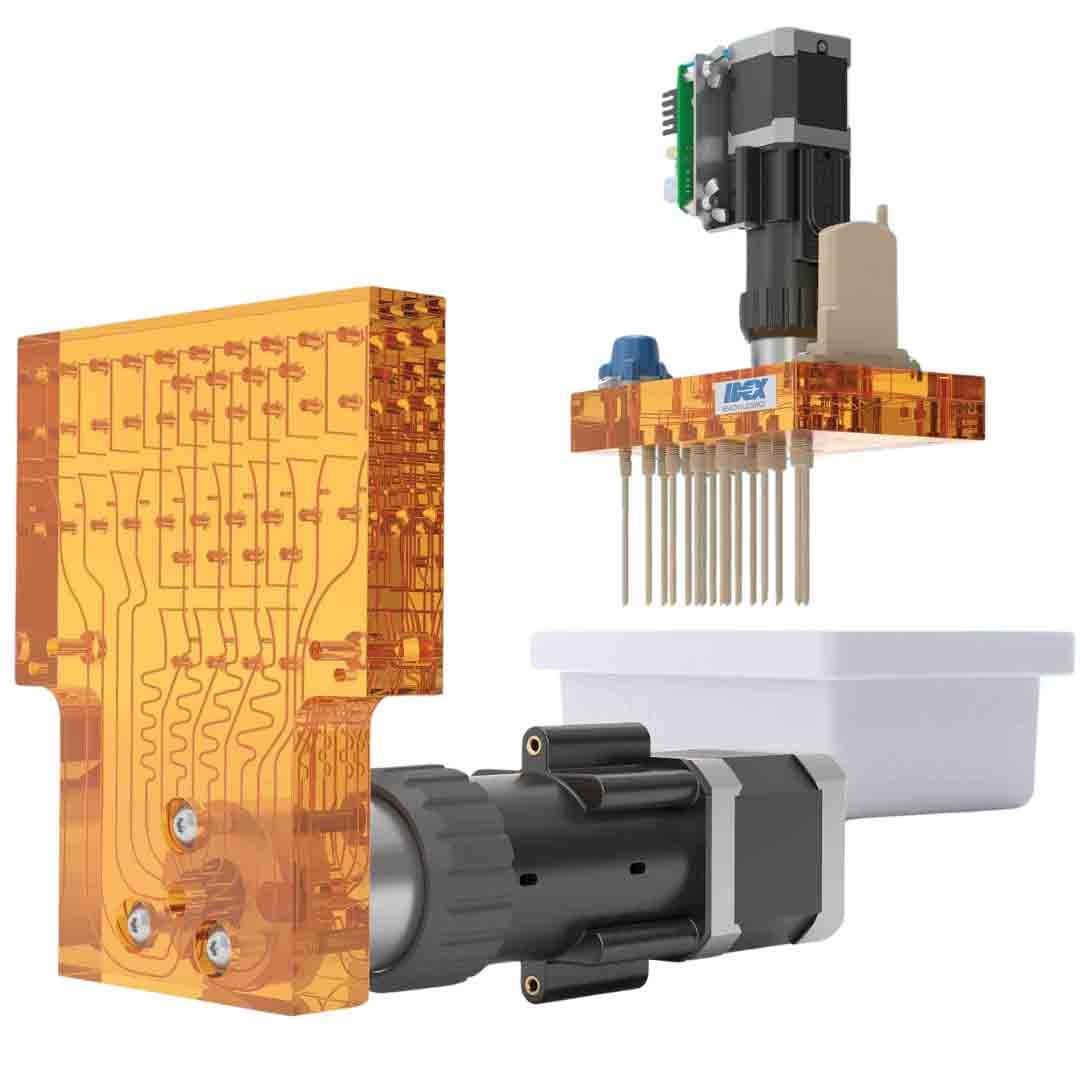

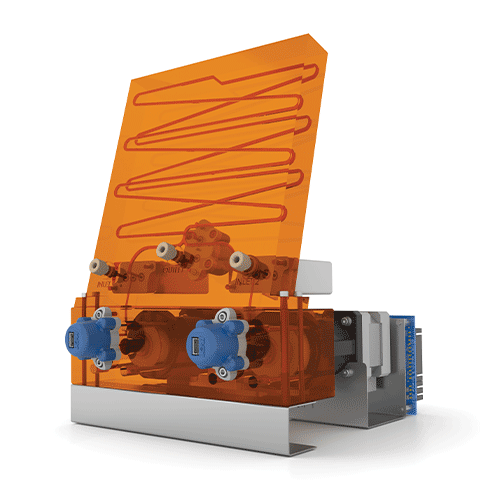

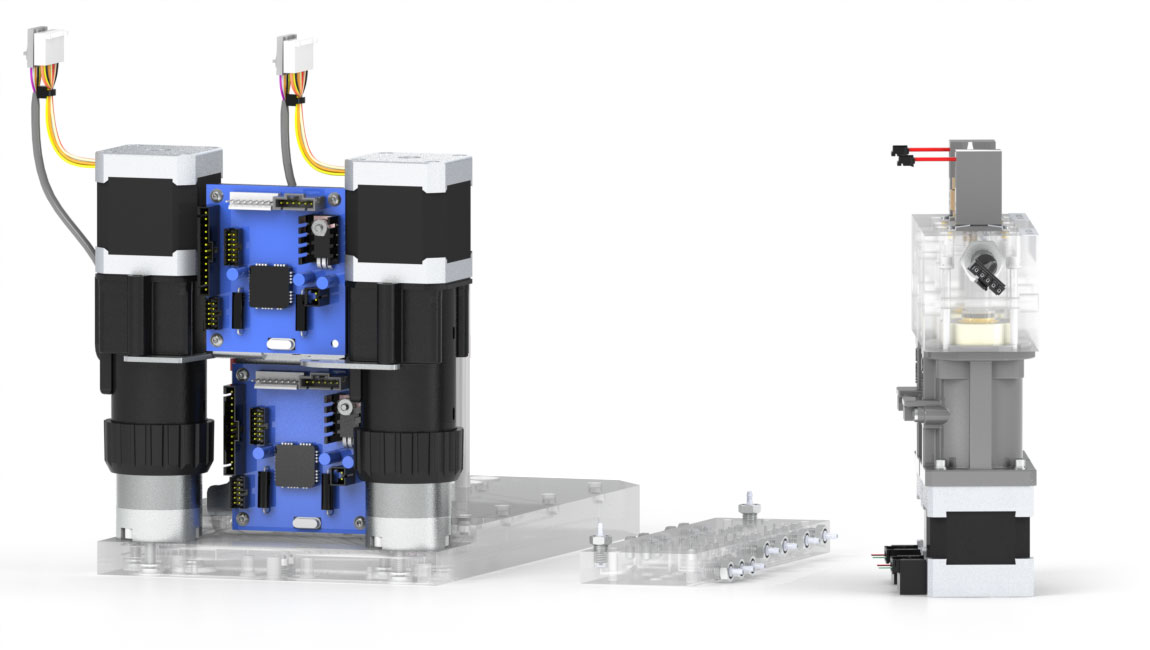

Manifold assemblies create a fluid distribution system that streamlines your fluidic system to control all reagents—inlet ports to outlet ports—to create a clean and organized flow path. Fluidic components can be integrated into a manifold assembly, which reduces plumbing complexity, minimizes the risk of leak points, and saves time for installation and servicing.

Key Benefits of a Manifold Assembly

- Consistent fluidic performance in every instrument, every time

- Enhanced system reliability

- Reduced complexity and the number of leak points

- Simplified installation and servicing

- Simplified reagent flow paths by integrating multiple fluidic components into a unified fluidic system

- Completely customizable

Complete Customization with Integrated Manifold Assemblies

At IDEX Health & Science, we don’t just build components, we create innovative solutions that maximize the performance of your entire fluidic pathway.

- Manifolds: Diffusion Bonded and Machined

- Rotary Shear Valves

- In-line Degassers

- Sensors: Pressure, temperature, conductivity

- Connections: Probes, tubing, and fittings

- Pumps

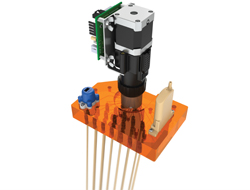

Manifold Valve Assembly

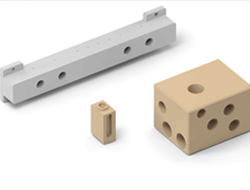

A manifold valve assembly is used for fluid management in your instrument platform. Rather than the valve being connected by tubing and fittings, the valve is mounted directly onto a PEEK, acrylic, or Ultem manifold. Multiple valves can be mounted onto a single manifold, eliminating excess lengths of tubing and negating the need for overfilling reagent lines.

Types of Manifolds We Offer

Manifold Assembly Configurations

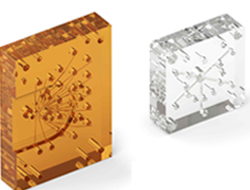

Computational Fluid Dynamics

Using computational fluid dynamic modeling, IDEX Health & Science offers instrument developers an option to analyze how their fluidics will operate before committing to expensive prototypes. Developers in this space can characterize the functionality of their hardware in weeks instead of months in the prototyping feedback loop. Start your project on the right foot with fluidic simulation and modeling.

Life Science Applications for Manifold Assembly Integration

From a manifold valve assembly to a full fluidic manifold assembly, you can create an elegant, unified, and reliable solution for fluid management with IDEX Health & Science.

Questions about manifold assemblies, or ready to get started?

Contact us today to speak with an expert about your fluidics platform needs.

*Required Field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.