The DGC-020 Degasser

Dissolved Gases Don't Stand a Chance

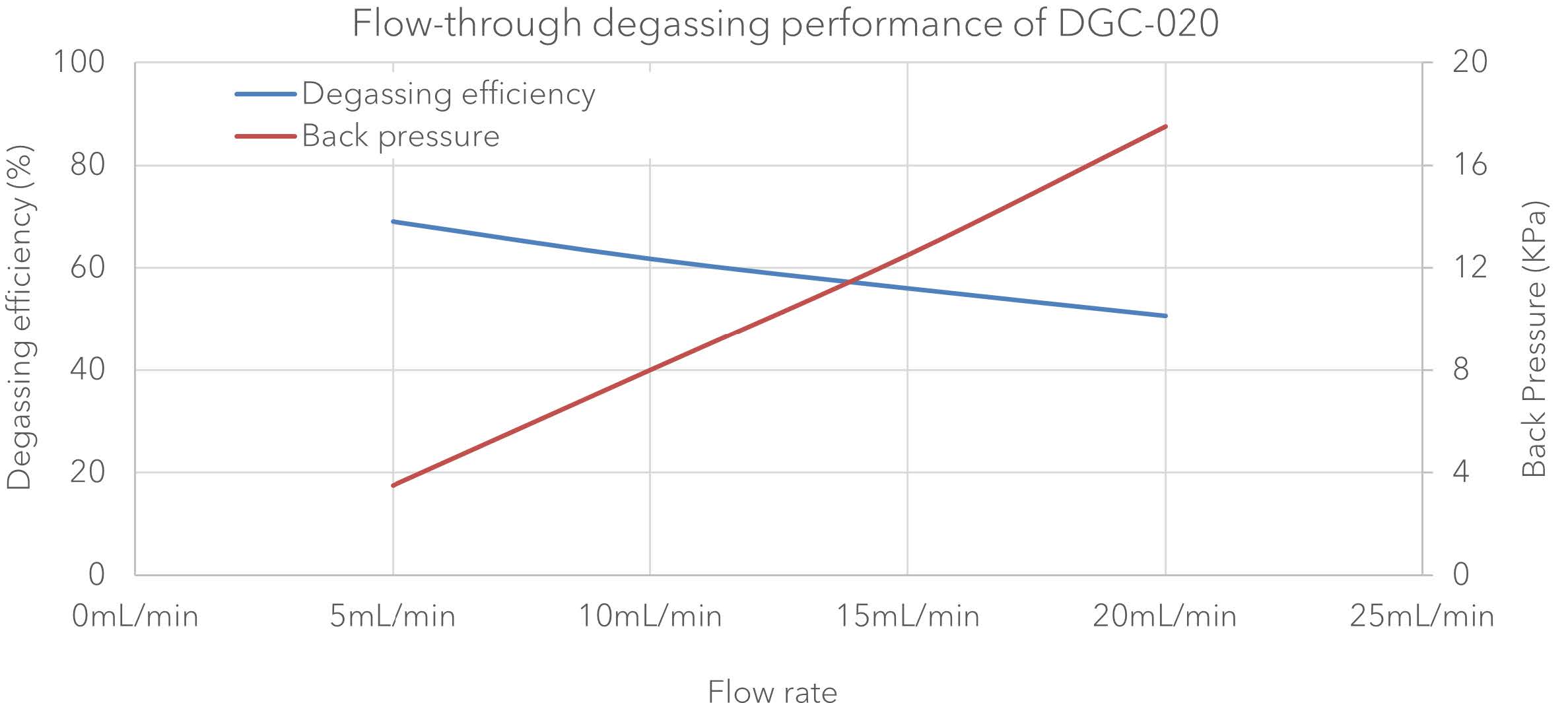

Fluidic degassers have an essential role in your fluidics platform—ensuring accurate aspiration and dispensing of your critical reagents. Our new DGC-020 degasser removes dissolved gases in the 5-20 mL/min (80-330µL/sec) flow rate range before bubbles form and cause unwanted system disruptions.

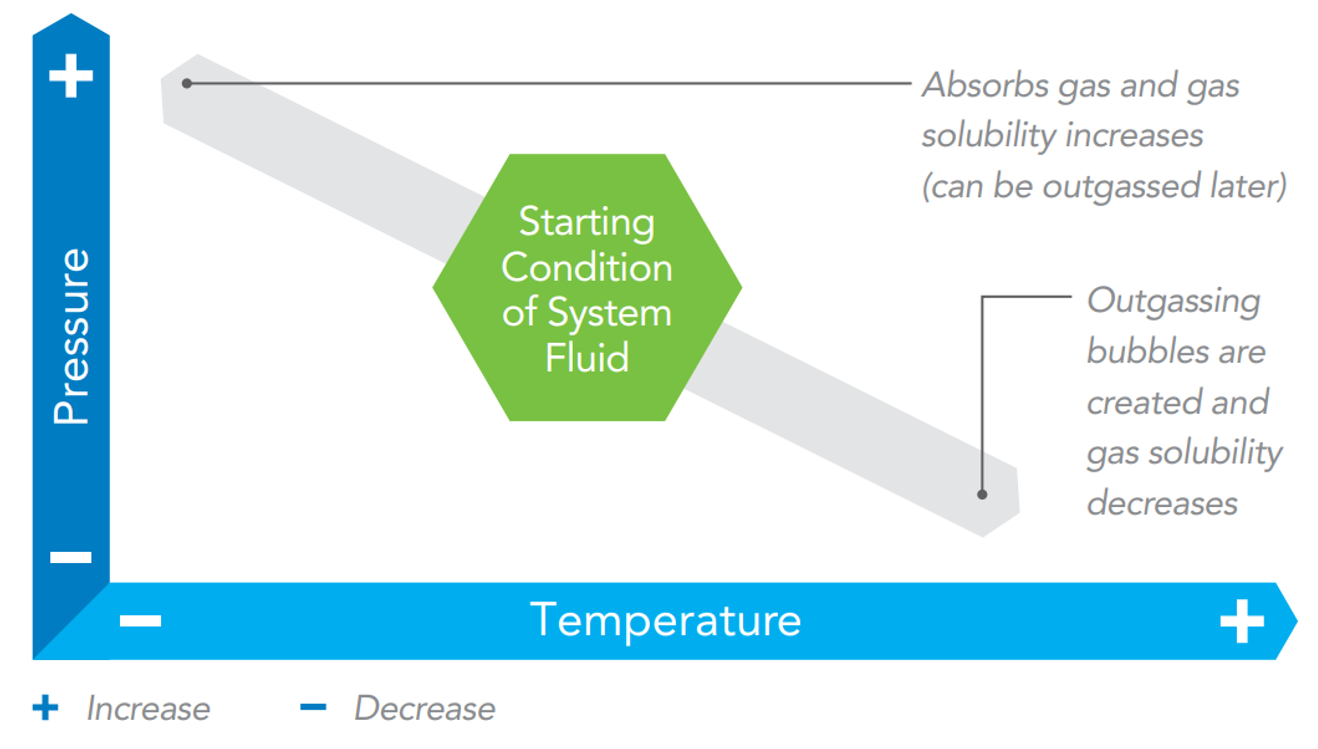

Bubbles can form when system reagents experience temperature or pressure changes. The DGC-020 is a silicone degasser removes dissolved gasses from the reagent before they are pulled into the system and outgas when the solubility levels change. This degasser is perfect for instrument developers in the clinical chemistry (IVD), Next Generation Sequencing (NGS), and Proteogenomic space.

Whether combined with your system vacuum source, or a dedicated vacuum pump from IDEX Health & Science, you will experience superior system operation and reduced worry about variability in your fluid dispensing.

Lead with Superior Degassing Performance with Our New Fluidic Degasser

Silicone Degasser

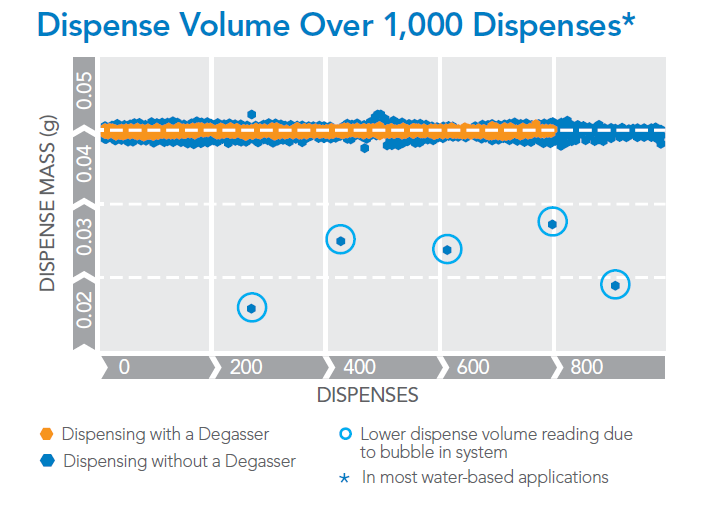

Removes dissolved gas before it becomes bubbles causing disruption during fluid dispense and optical detection.

Flexible Form Factor

Allows customers to integrate degasser directly into platform or mounted onto a custom manifold.

Proven Degassing Technology

Provides long lifetime operation with little need for maintenance for aqueous buffers and reagents.

A Bubble Buster at Work

The core functional element of this inline degasser is a fluid path lined by a highly permeable silicone-like membrane. Fluid flows through the membrane pathway, while the space surrounding the membrane is evacuated. A PID controlled IDEX Health & Science vacuum pump holds a precise vacuum level driving the active removal of dissolved gases across the membrane.

The plot shows the reference degassing efficiency of degassing chamber DGC-020 tested under various flow rates. The degassing efficiency represents the percentage of removed dissolved oxygen with respect to its saturation concentration. The curve shows a typical minimum performance profile gained at 25 °C using deionized water and a vacuum level of 16.7 kPa. The chamber was operated with negligible back pressure connected to the discharge side of a continuous pump. Oxygen content was monitored using a dissolved oxygen sensor while the flow rate was measured using a mass flow meter.

Anytime system conditions shift in a way that reduces the gas solubility of a fluid, outgassing occurs and bubbles form. If conditions change towards the lower right at any point in the fluid path, bubbles will be generated.

Our new fluidic in-line degasser is engineered for your laboratory and analytical life science applications where bubbles are problematic:

Why Trust IDEX Health & Science for Your Fluidic Degassing Needs?

IDEX Health & Science is a leader in degassing technologies in the analytical solutions / life science market. We help you tackle your degassing challenges in your clinical laboratory with innovative technology from the component level through complex fluidic engines. Our technology is world-renowned for quality and efficiency in removing gas molecules and eliminating bubbles in your flow path creating stress-free workflow solutions in your clinical laboratory. Contact us to get started.

Lead with superior degassing performance.

Fill out the form to get started on your degasser project

*Required Field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.