Accelerate Your Flow with our New 12/13 Selection and Distribution Valve

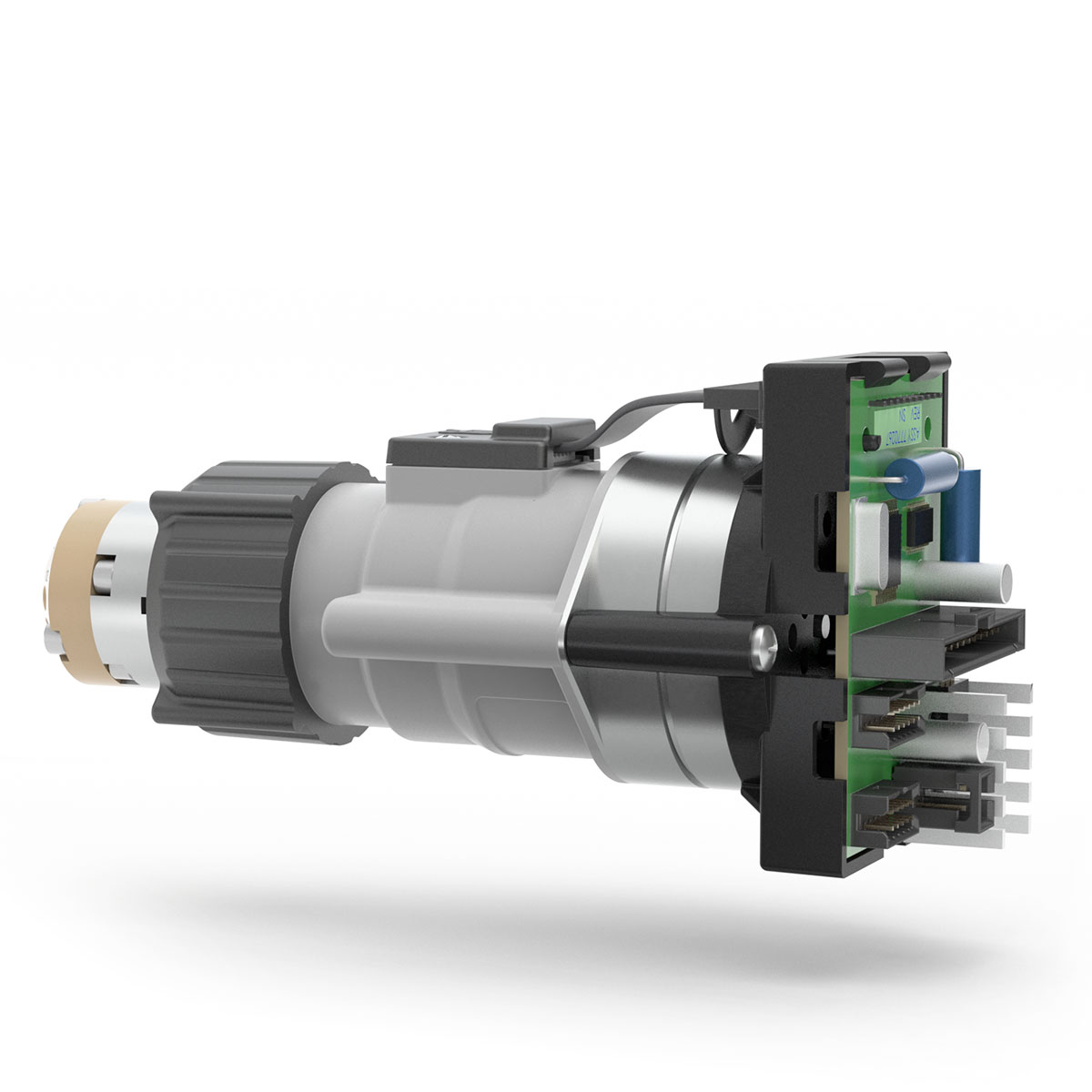

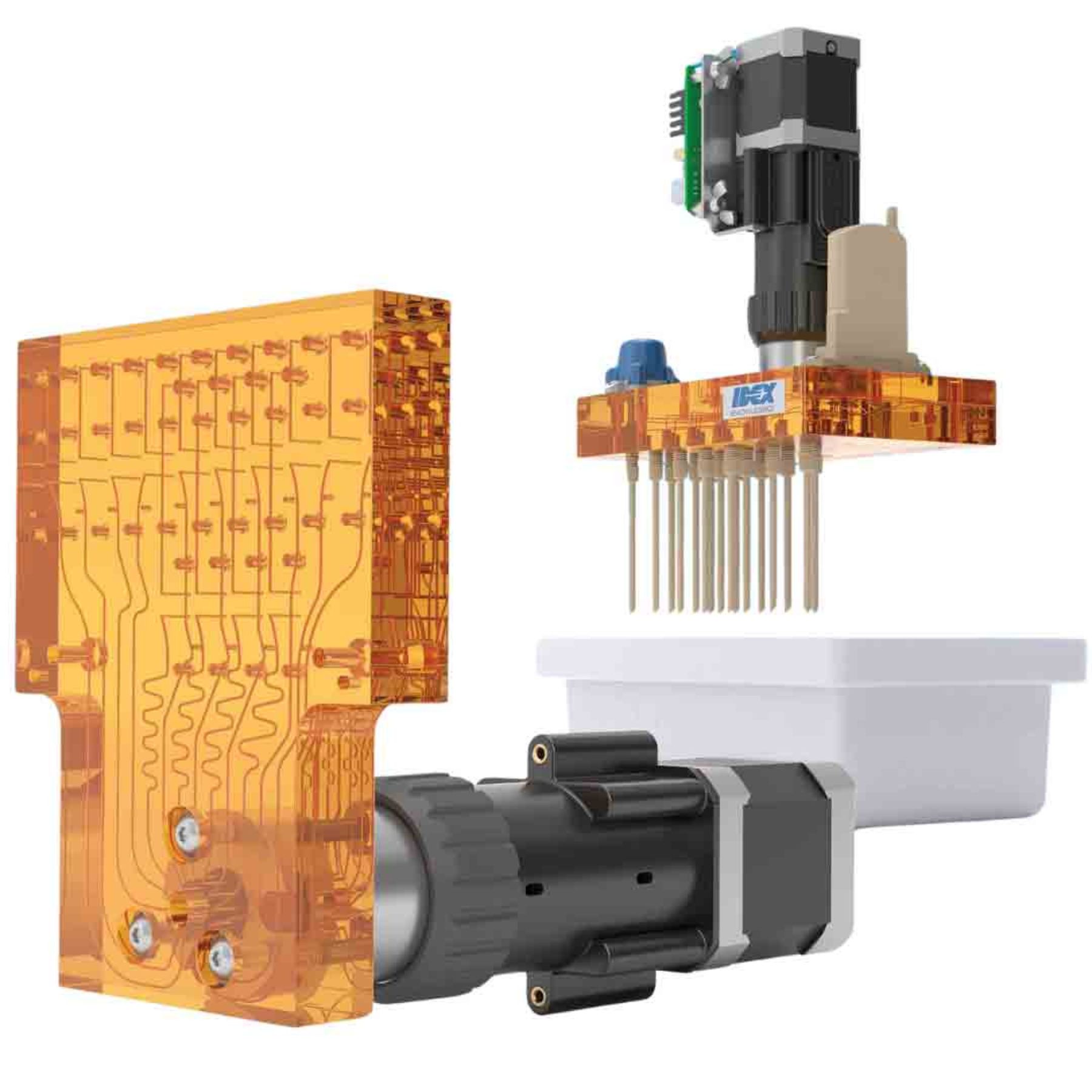

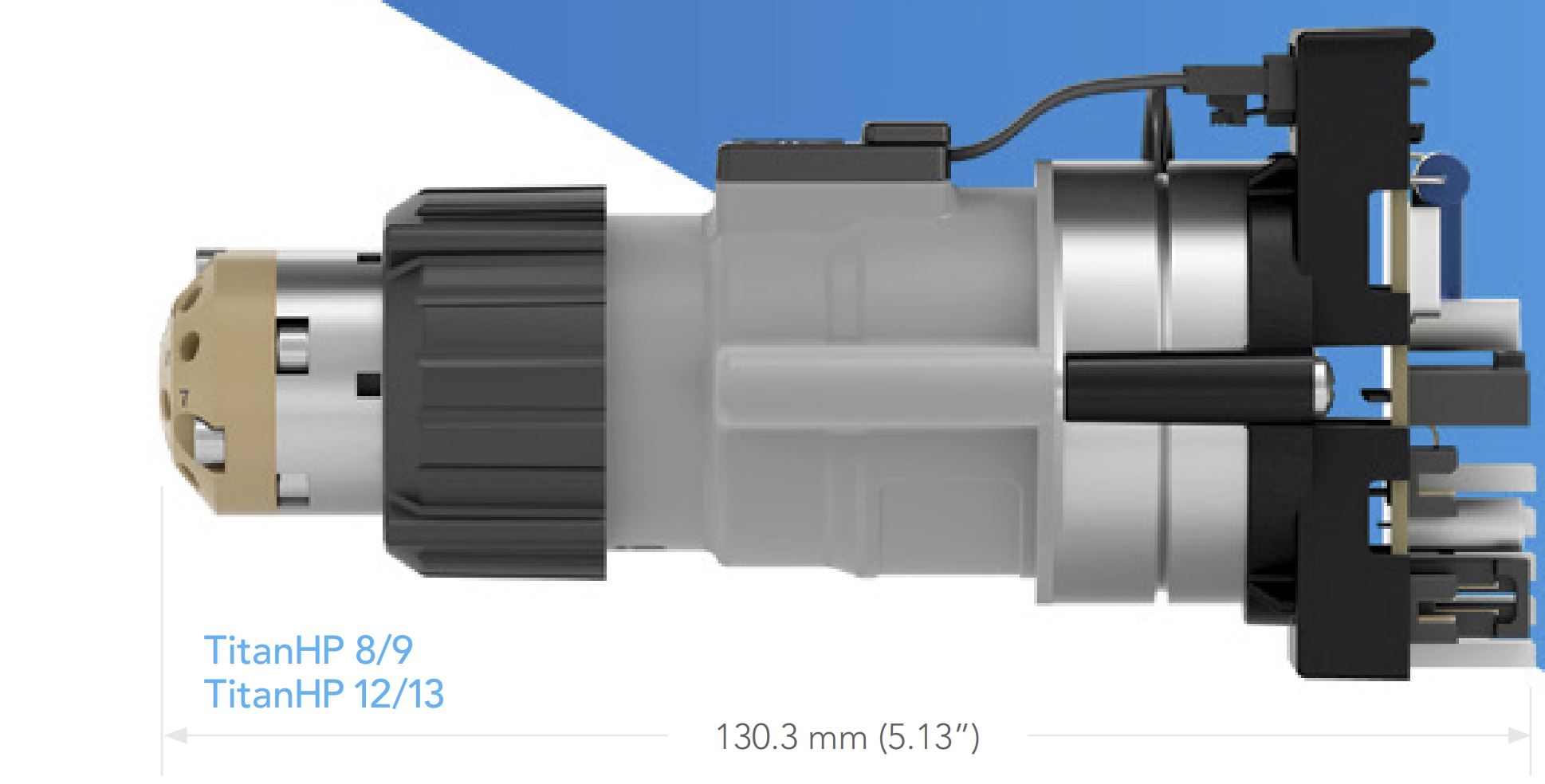

Building on our legacy of high-performance valve solutions, IDEX Health & Science proudly introduces the 12/13 TitanHP—engineered to deliver exceptional fluidic precision and long-lasting durability for the most demanding life science applications. The 12/13 TitanHP is a 12-position, 13-port biocompatible valve that can be used with 6-40 fittings or mounted to a manifold for seamless system integration. It’s ideal for life science customers using flow rates 200µL/sec or less, looking for a small footprint valve to integrate into their platform.

The TitanHP 13-port valve has been tested over two million cycles, proving a reliable solution for reagent distribution across your instrument platform. It also includes a PCB, which can easily be integrated into any breadboard design, along with our IDEX Health & Science Library (powered by Python™), enabling accelerated integration.

Unmatched Life Science Valve Performance

| Biocompatible | Enables the development of life science instrumentation without concern of impacting DNA, proteins, peptides, or other biological material. |

| Quality-built and tested for long-lasting use | Long lifetime of operation |

| Small form factor valve | Enables benchtop design and management of multiple reagents |

| Integrated stop flow position | Allows users to pressure check their platform and hold all flow from the valve |

| Custom manifold mounted valve or, standalone with 6-40 fittings | Fully customizable for integration into your platform |

| Includes PCB (printed circuit board) | Enables faster adoption using IDEX Health & Science Library--powered by Python programming |

| Low swept volume | The valve's design minimizes dead volume, reducing the risk of sample carryover and contamination |

| Fast fluid switching valve | Ability to actuate fluids under 3 seconds |

Compact and Consistent—Small Form, Big Results

TitanHP 12/13 is a small form valve that enables benchtop design and management up to 12 reagents.

Interested in learning more about the TitanHP valve series?

Fill out the form to get started. Request access to CAD models, our Valve Solutions Brochure and Custom Valve Design White Paper.

*Required Field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.

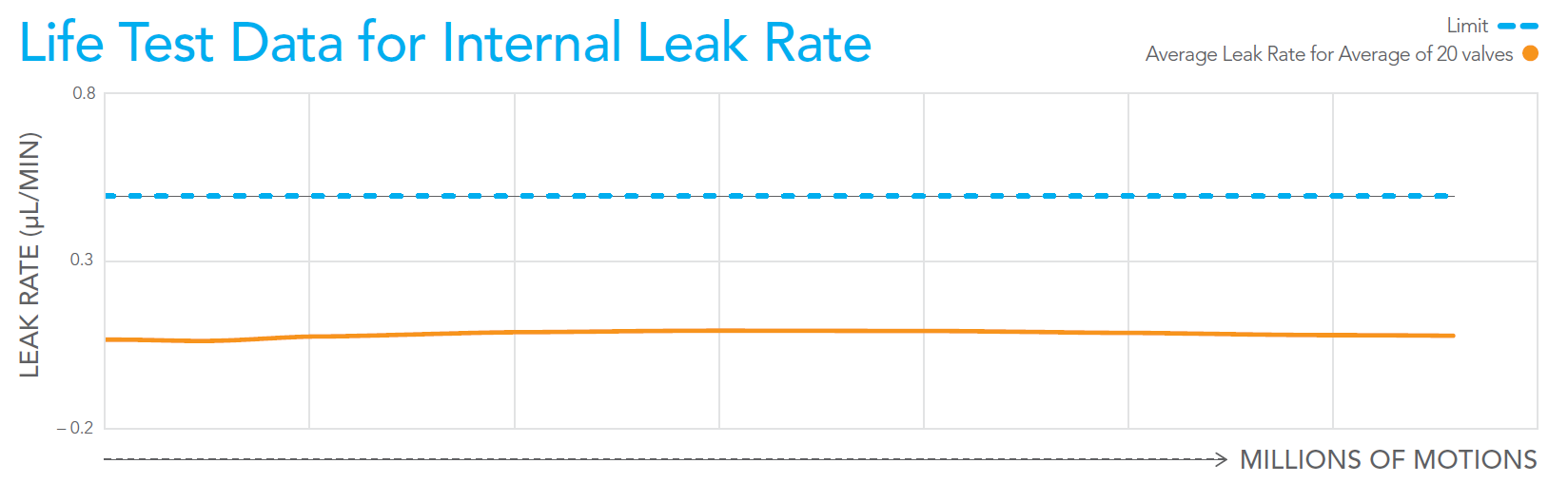

Performance Powerhouse—Tested Over Two Million Cycles

During development valve sealing materials are tested to ensure long lifetime and robust performance. This graph illustrates the average of 20 valves cycled with a 1X PBS solution over millions of cycles. Interval testing looks for internal port-to-port leakage. The rugged sealing surfaces did not suffer from scoring or internal leak failures over the course of the run.

Our valve development process tests the durability of sealing surfaces for blockages that can increase system backpressure over time. From this plot of the average of 20 valves cycled with a 1X PBS solution at 80 µL/sec over millions of cycles, it is seen that there are minimal increases to the system backpressure, demonstrating material ruggedness and performance.

TitanHP 12/13 Valve is Ideal for Low-Pressure Applications:

Partner with IDEX Health & Science to discover our high level of engineering support and commitment to your valve life science instrumentation.

Related Resources

Custom Rotary Shear Valve Video

Streamline your complex reagent flow path.

IDEX Health & Science Library

Spend less time programming and more time for discoveries.