Finding Your Optical Filters Guide

The Customer Journey with Semrock Optical Filters

Deciding on a set of optical filters for a new fluorescence-based product is a complex task that requires careful planning to assure a successful outcome. Complicating factors include the need for fast timeline, reliable production, and budget constraints.

IDEX Health & Science has empowered this search process with its line of Semrock® optical filters. Our process is based on three key assets: Team, Tools, and Technology.

Team: Our staff of Application Scientists who understand your requirements, with years of collaborations with engineers and scientists on simple to sophisticated projects, backed up by our expert RD&E staff who design the filters with innovative approaches.

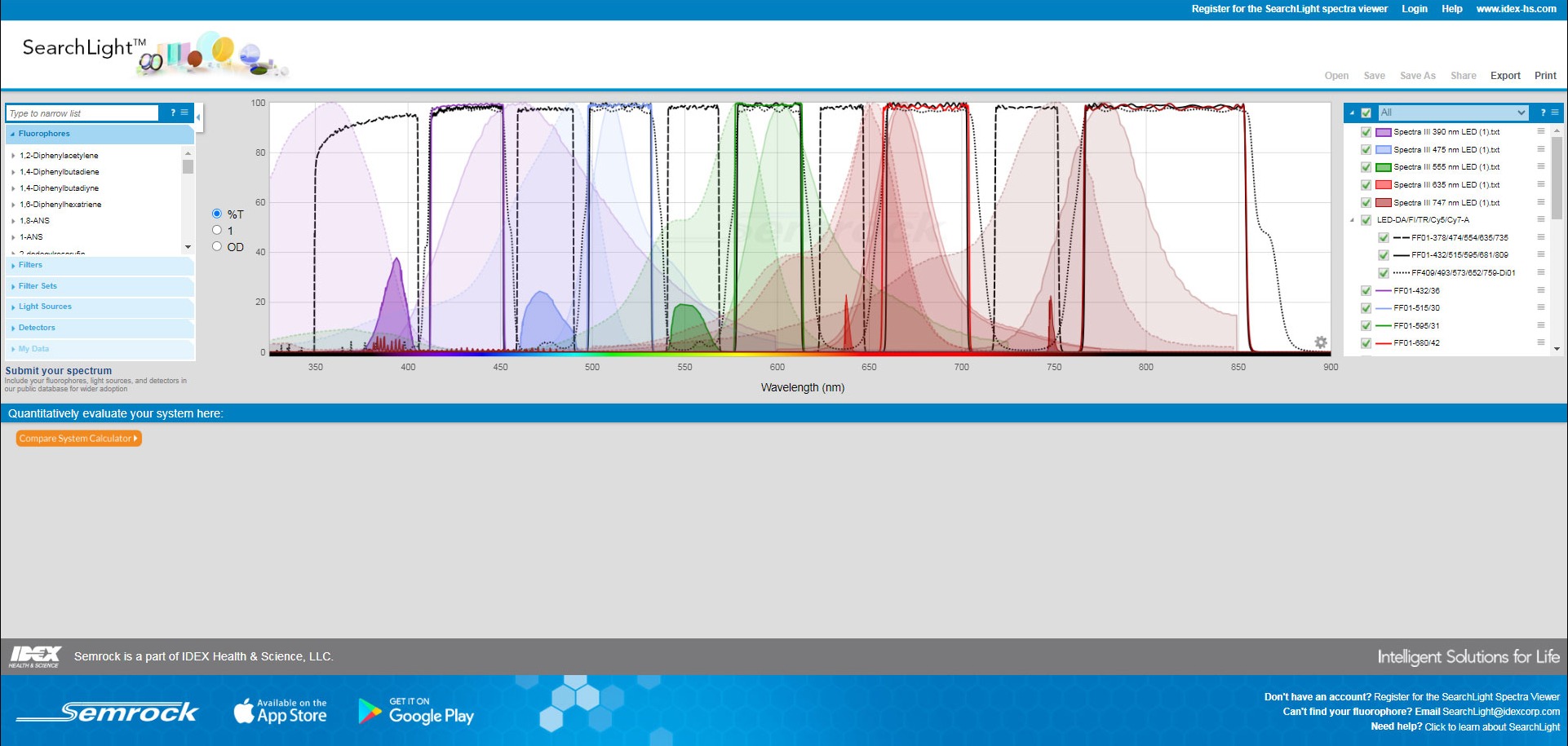

Tools: Our software that both customers and team use to model filter behavior. Key among these is SearchLight™, a simulation tool for modeling the spectral behavior of your optical system, including filters, excitation sources, microscope components, fluorophores, and detectors. SearchLight allows you to flexibly refine filter specifications, model system behavior, and drive optimization.

Technology: Our system that continues to produce the most reliable and highest performance optical filters in our industry, based on our Manufacturable Specifications approach and employing our KolaDeep™ Spectral Measurement System.

Learn about partnering with us by exploring:

- Your Filter Options (catalog, custom, or hybrid)

- The steps in the Customer Journey

Connect with an Optical Filters Expert and Access our Finding Your Optical Filters Guide

*Required Field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.

Filter Options: Catalog

Catalog filters are designed for use in standard microscopes, or in similar optical systems having an AOI Range near 5° at the bandpass filters. Our catalog database offers hundreds of catalog filters.

- Pros: Fast delivery and customizable (see sidebars)

- Cons: Limited to the more standard fluorophores; custom filters may be better matches to price / performance requirements.

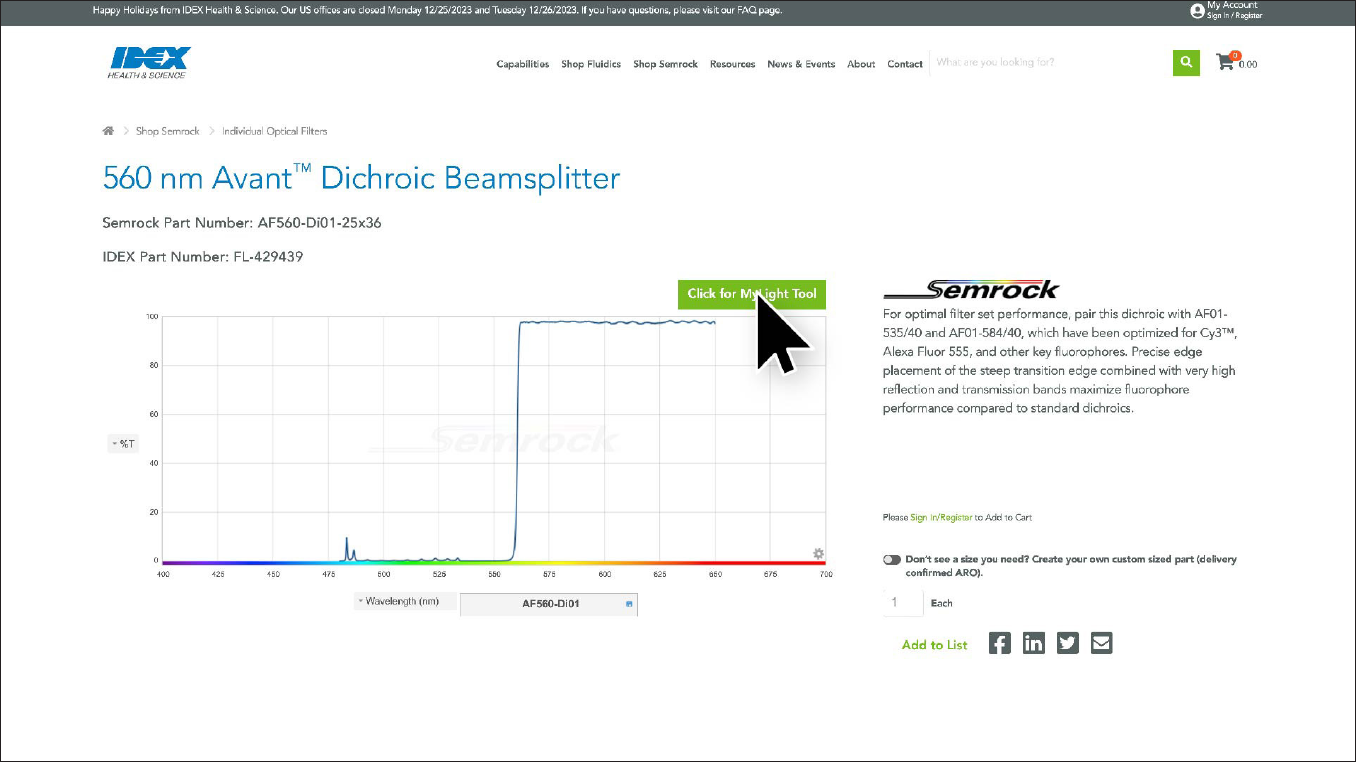

The SearchLight analysis tool can be most helpful here, as its database has spectra of all catalog filters, fluorophores, etc., and your team can easily collaborate with each other and with our Applications Scientists through shared SearchLight sessions. Click the link for the SearchLight session shown in the illustration below, to explore its features. The MyLight™ tool, found on the webpage of each catalog filter, can be used to model the effect of AOI on spectra and polarization.

New Lead Times for 2024

- 2-5 business days delivery for guaranteed in-stock catalog filters and sets

- 1 week for custom filter design quotation

- 4 weeks delivery for custom coatings

- A minimum order quantity as low as 1 to 10 filters

Easily Customize Your Catalog Filters

- Custom sizes

- Nonstandard dimensional tolerances

- Custom Clear Aperture

- Edge blackening

- Colored paint part marking

Filter Options: Custom

Can’t find the filters you need in our catalog? We offer custom coating filter designs tailored specifically to your system needs. Though the initial prototype filter cost will be higher than using standard catalog filters, it can often save money in the long term by assuring you immediately get the features you need.

- Pros: Exactly what the system demands, optimized for specific format, light sources, fluorophores, and detectors, with no need for updates once the system transitions from prototype to production

- Cons: Slightly longer lead time (but still exceptionally fast), higher initial investment

An alternative is to choose a hybrid mixture of catalog and custom filters.

- Pros: Reduces the initial investment and development time with a smaller number of custom filters

- Cons: Slightly longer lead time (but still exceptionally fast), higher investment in prototyping

The Stages of the Customer Journey

These phases apply to OEMs with ramp-up in mind, as well as to customers building one-off systems.

- Share preliminary requirements and decide on filter specifications:

- The more you share about your system, the better we can optimize the optical performance: light sources, detector, fluorophores, application, and optical layout.

- IDEX Health & Science offers a standard mutual NDA to all customers. Our legal team may review customer-provided NDAs in some cases.

- See the Custom Filters Specifications Form for a handy guide to specifications.

- Please share production level expectations so we can ensure the right coating platform for your needs.

- After discussion and modeling, the customer and our team agree on the filter specifications.

- Finalize filter designs and issue a quotation:

- We use Manufacturable Specifications, which means we build in manufacturability when writing specifications. This ensures that the filter specifications hold for every individual filter delivered.

- The filter design team converts the specifications into filter designs. In some cases, specifications are adjusted to assure manufacturability and yield. This process can take one week or more depending on overall system complexity.

- You will receive a drawing containing the specifications and simulated optical response data, which can be loaded to SearchLight for modeling your system.

- Once the specifications and optical performance pass customer review, your Key Account Manager provides a quotation.

- When the customer purchase order is received, IDEX Health & Science sets up the account, the customer purchase order is processed, and a promised ship date is provided.

- Before being shipped out, every filter is thoroughly inspected to ensure they meet our standards for high quality and superior performance.

- Filters are delivered to the customer site, and performance testing starts. Our team is most interested in results, and any small issue is worked on with full transparency. Traceability of our filters means minimal lost time tracking any issues.

- Let us know the results! Do you need to adjust some specifications? Let’s partner!

“Once we get your filter specifications, we carefully consider what they mean for product implementation. We look at how all the filters will work together, as opposed to just looking at each filter in isolation. The whole system must be optimized for your fluorophores, light sources, and detectors.” – Nicole Zombotti, Key Account Manager

Moving to Production

All our catalog filters are already able to support your production level needs!

For a custom coating design, it is important to know production level volumes before we manufacture the first filters. We can then select the appropriate coating platform to ensure consistent delivery throughout early stage and ramp-up customer production phases.