PFAS Free Silicone Degassing for Life Science Applications

![]()

Optimal Degassing Performance for Aqueous Reagents

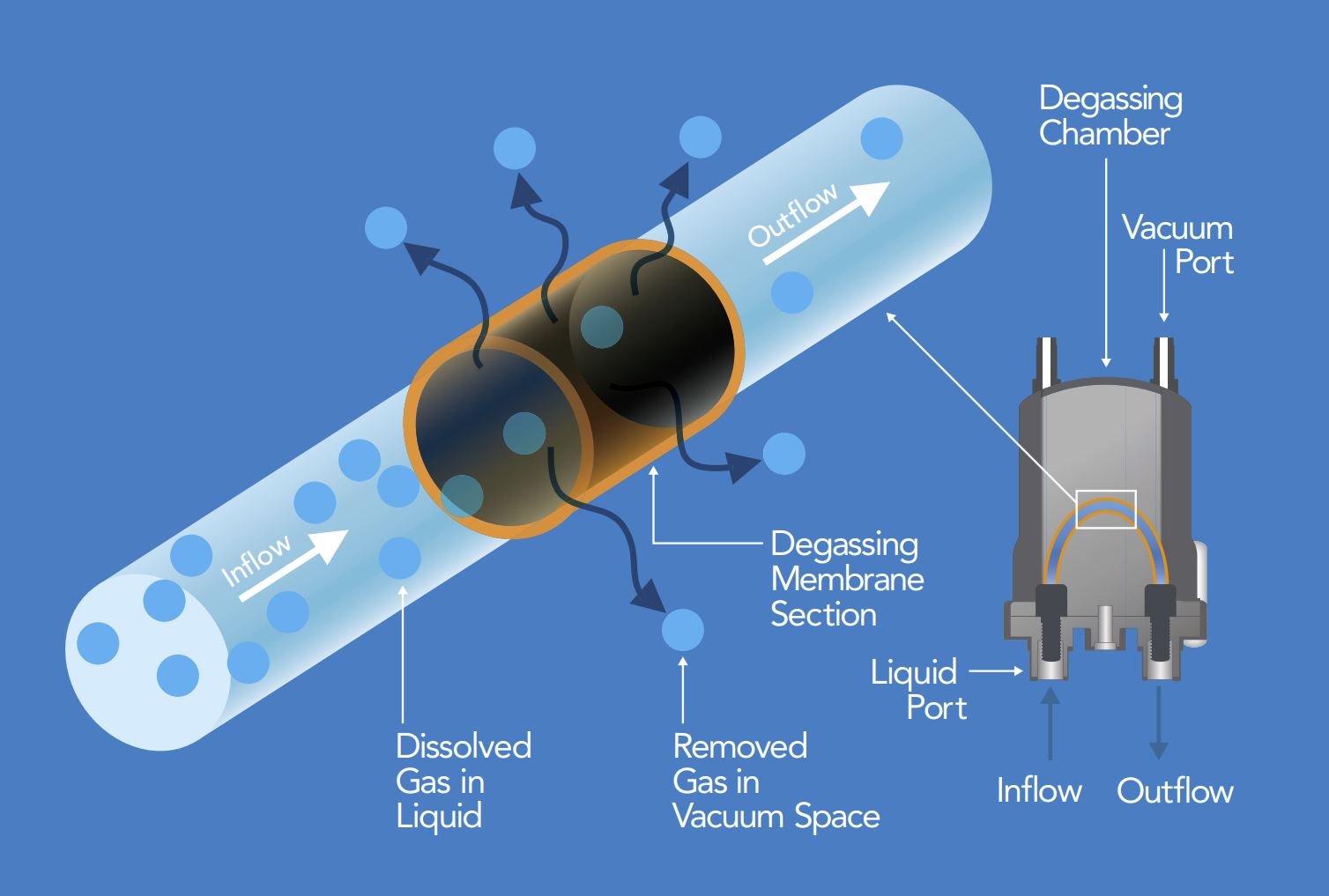

Dissolved gasses system fluids lead to bubble formation that inhibits peak system performance. Changes in system pressure, temperature, or reagent mixing can cause bubbles to outgas into the flow path, creating inaccurate aspiration and dispense functions and disrupting optical detection.

Our Solution—DGC-020 Silicone Degasser

The DGC-020 inline silicone degassing chambers actively remove dissolved gases before they form bubbles, ensuring maximum uptime and performance. It can be integrated into your system as a stand-alone unit for use with your system vacuum, combined into a bracket with an IDEX Health & Science vacuum pump, or mounted onto a custom manifold for a fully integrated solution. This degasser is also PFAS free.

Life Science Applications:

- Water / Aqueous Chemistries

- Benchtop Clinical Chemistry & Immunoassay

- Flow Cytometry

- NGS Applications

- Spatial Biology

- Multiomics (Genomics, Proteomics)

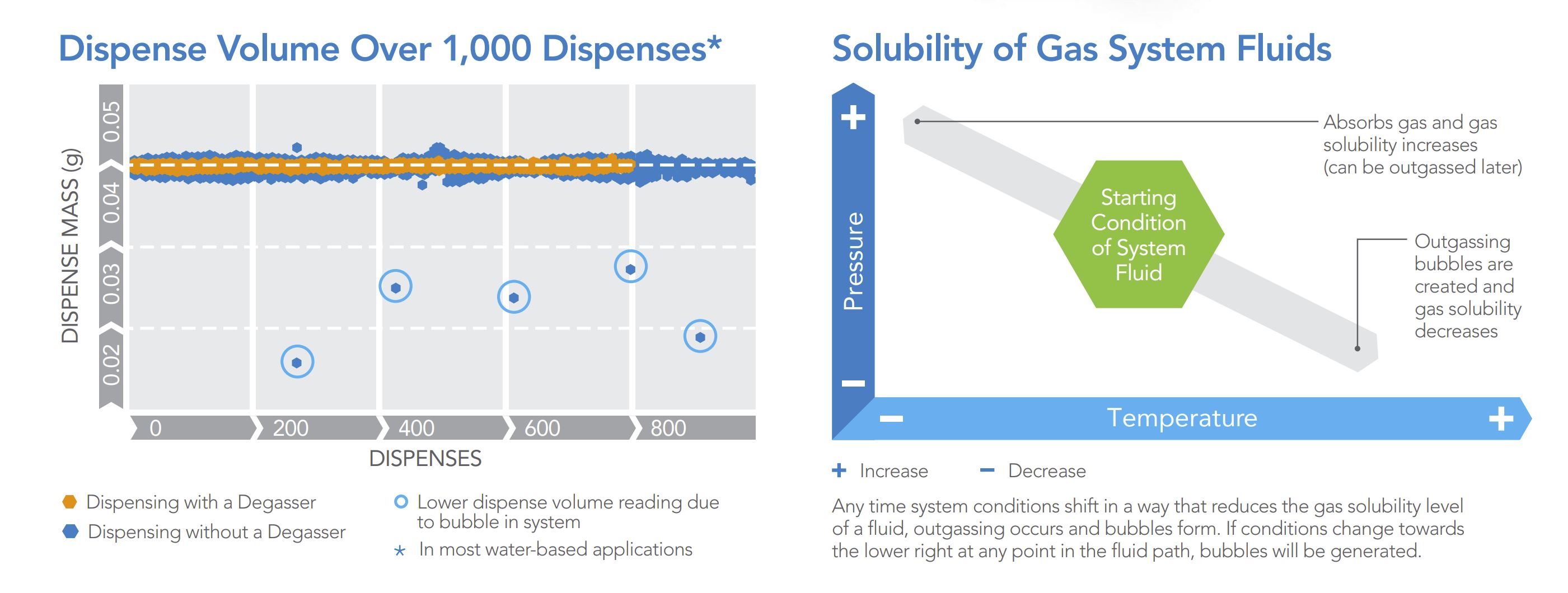

How It Works

The core functional element of this inline degasser is a fluid path lined by a highly permeable silicone-like membrane. Fluid flows through the membrane pathway, while the space surrounding the membrane is evacuated. A PID-controlled IDEX Health & Science vacuum pump holds a precise vacuum level driving the active removal of dissolved gases across the membrane.

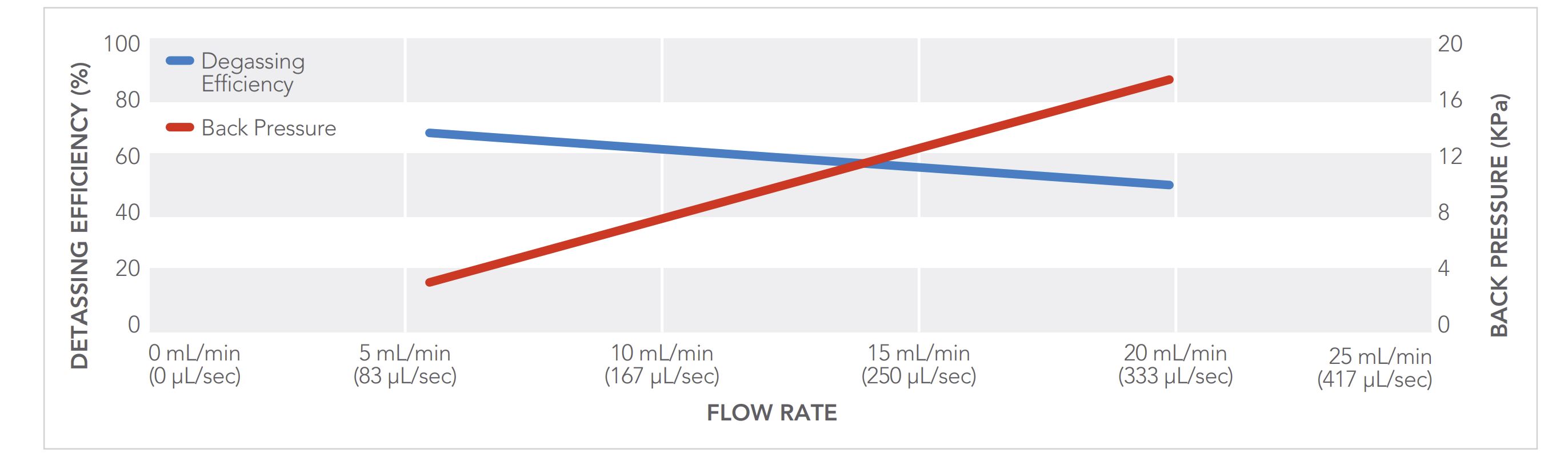

Typical Performance: Flow-Through Aqueous Degassing Performance of DGC-020

The plot shows the reference performance of degassing chamber DGC-020 tested under various flow rates. The blue line shows a typical minimum degassing efficiency profile gained at 25 °C using deionized water and a vacuum level of 16.7 kPa. The degassing efficiency represents the percentage of removed dissolved oxygen with respect to its saturation concentration. Oxygen concentration was monitored using a dissolved oxygen sensor while the flow rate was measured using a mass flow meter. The red line shows a typical back pressure profile gained at 25 °C using deionized water without vacuum.

DGC-020 Silicone Degasser Specifications

Parameter | Value |

| Product Alias | DGC-020-153881 |

| Product Number | 115388100001 |

| Other Wetted Materials | Ethylene propylene diene monomer (EPDM); Polyphenylene sulfide (PPS) |

| Recommended Liquid Connection | Male 1/4-28UNF nut preferably with a softer ETFE ferrule |

| Recommended Vacuum Connection | Low gas permeability 3 mm ID elastomeric tube |

| Recommended Degassing | Vacuum 16.7 |

| Recommended Min/Max Liquid Flow Rate | 5 / 20 mL/min; ~ 80 / 330 μL/sec |

| Pressure Drop | (Water 25°C, Maximum Operating Flow Rate) < 20 kPa |

| RoHS / REACH Compliance | YES |

Learn about our DGC-020 Silicone Degasser

Fill out the form to get started on your degasser project

*Required field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.

Related Resources and Products