Guide to Medical Device Tubing

Medical tubing is used for transferring fluid, drainage of fluid, and guiding electrical cables. Tubing used for medical device applications requires precision, reliability, and safety. Materials, dimensions/tolerances, optical clarity, and chemical resistance are critical factors in ensuring the tubing functions properly without risks to patients and healthcare providers.

What is Non-Medical Grade Tubing?

Not all tubing used in medical applications is classified as “medical grade tubing”. Tubing products may be used for medical devices, but not specifically designed or tested for direct medical applications. This type of tubing is known as non-medical grade tubing and is used in:

- Non-patient contact areas: Commonly used in medical devices that do not come into direct contact with patients.

- Prototype or development stages: During development stages, manufacturers of medical device tubing may use non-medical grade tubing for prototypes to test and assess the functionality.

- Auxiliary components: Used in non-medical applications such as carrying electrical cables or sensor wires through devices.

- Non-critical fluid or gas transfer: Used for non-critical transferring of fluidic or gases in laboratory equipment or devices used for diagnostic purposes

Our non-medical grade tubing is manufactured for internal instrument components or non—invasive medical applications—where direct patient contact is not needed or when the tubing is used in conjunction with other materials. While this type of tubing might be made from the same materials used in other critical medical applications, it is intended for less critical medical device uses.

Benefits of Non-Medical Grade Tubing:

1. Cost Efficiency: Using non-grade medical tubing can significantly reduce manufacturing costs.

2. Flexibility: Non-medical grade tubing is more flexible. There are more options for materials, and you can choose a specific material based on the application. For example, you can customize your tubing to meet unique flexibility needs, lifespan requirements, and resistance to specific chemicals.

3. Non-Critical Applications: Because regulatory requirements are different from medical grade tubing, non-medical grade tubing is ideal for non-critical medical device applications.

IDEX Health & Science medical device tubing can be used in a variety of applications including urology, endoscopy, neurovascular, neuromodulation, ear, nose, & throat, and cardiac intervention. Our extrusion tubing capabilities are a cut above the rest with tight tolerances designed to your exact specifications, saving you time and complexity. We extrude, cut and form, test, and label every piece, so you receive a single assembly that’s ready to integrate directly into your medical device tubing system or platforms.

IDEX Health & Science Capabilities for Medical Device Tubing:

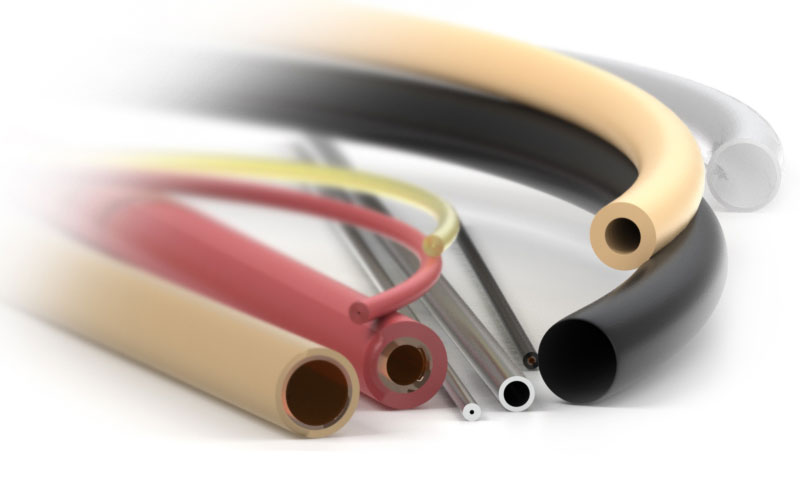

- Custom medical extrusion technology: Custom extrusion runs available for non-stocked sizes and extrusions (Tolerances down to +/- 0.0005”).

- Range of thermoplastic elastomers: Known as TPEs, we can manufacture materials with both thermoplastic and elastomeric properties, which are ideal for medical tubing applications.

- Engineering resins: Multiple tubing materials available, including high-purity grades (PTFE, ETFE, PFA, High Purity PFA, and PEEK tubing option available.

- Durometer (specification): We have the ability to manufacture elastomeric tubing of varying durometers.

- Cut-to-length: We have custom bulk and custom-cut lengths available.

IDEX Health & Science tubing with a large diameter

IDEX Health & Science tubing with a small diameter

LEARN MORE ABOUT OUR MEDICAL TUBING CAPABILITIES