Laser Damage Threshold

Laser damage to optical filters is strongly dependent on many factors, and thus it is difficult to guarantee the performance of a filter in all possible circumstances. Nevertheless, it is useful to identify a Laser Damage Threshold (LDT) of pulse fluence or intensity below which no damage is likely to occur. Laser damage may be broadly classified into two types: absorption-driven and dielectric-breakdown damage. Which type dominates depends on the material properties (absorption coefficient, specific heat, melting temperature, as well as defects that cause scattering and concentrated electric field effects), geometric properties of the sample (thickness, homogeneity, surface morphology, etc.), and of course the properties of the laser beam itself.

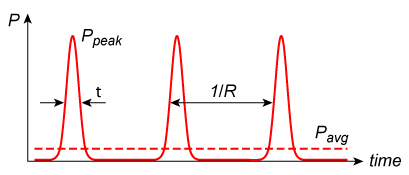

Pulsed vs. continuous-wave lasers: Pulsed lasers emit light in a series of pulses of duration  at a repetition rate R with peak power Ppeak. Continuous-wave (cw) lasers emit a steady

beam of light with a constant power P. Pulsed-laser average power Pavg and cw laser constant power for most lasers typically range from several milliWatts (mW) to Watts (W). The diagram and table

below illustrate and summarize the key parameters that are used to characterize the output of pulsed lasers.

at a repetition rate R with peak power Ppeak. Continuous-wave (cw) lasers emit a steady

beam of light with a constant power P. Pulsed-laser average power Pavg and cw laser constant power for most lasers typically range from several milliWatts (mW) to Watts (W). The diagram and table

below illustrate and summarize the key parameters that are used to characterize the output of pulsed lasers.

| Symbol | Definition | Units | Key Relationships |

| τ | Pulse duration | sec | τ = D / R |

| R | Repetition rate | Hz = sec-1 | R = D / τ |

| D | Duty cycle | dimensionless | D = R x τ |

| P | Power | Watts = Joules / sec | Ppeak= E / τ; Pavg = Ppeak x D; Pavg = E x R |

| E | Energy per pulse | Joules | E = Ppeak x τ; E = Pavg / R |

| A | Area of laser spot | cm2 | A = (π / 4) x diameter2 |

| I | Intensity | Watts / cm2 | I = P / A; Ipeak = F / τ; Iavg = Ipeak x D; Iavg = F x R |

| F | Fluence per pulse | Joules / cm2 | F = E / A; F = Ipeak x τ; F = Iavg / R |

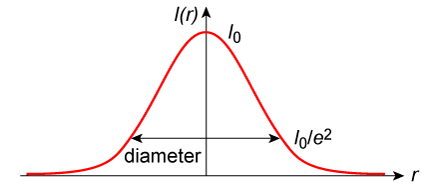

Note that because fluence and intensity on the surface of the component are critical parameters, the area of the laser spot is also critical. Even very high-power lasers may be transmitted through or reflected off of a durable optical filter if the spot size is sufficiently large to reduce the fluence and/or intensity. The diameter of a laser spot with a Gaussian profile is most accurately measured at the 1/e2 intensity points as shown in the diagram below.

Long-pulse lasers: LDTLP is generally specified in terms of pulse fluence for “long-pulse lasers.” Long-pulse lasers have pulse durations  in the nanosecond (ns) to microsecond (µs) range, with repetition

rates

R typically ranging from about 1 to 100 Hz. Because the time between pulses is so large (milliseconds), the irradiated material is able to thermally relax—as a result damage is generally not heat-induced, but rather caused

by nearly instantaneous dielectric breakdown. Usually damage results from surface or volume imperfections in the material and the associated irregular optical field properties near these sites, rather than catastrophic destruction of the fundamental

material structure. Most Semrock filters have LDTLP values on the order of 1 J/cm2, and are thus considered “high-power laser quality” components. An important exception is a narrowband laser-line

filter in which the internal field strength is strongly concentrated in a few layers of the thin-film coating, resulting in an LDTLP that is about an order of magnitude smaller.

in the nanosecond (ns) to microsecond (µs) range, with repetition

rates

R typically ranging from about 1 to 100 Hz. Because the time between pulses is so large (milliseconds), the irradiated material is able to thermally relax—as a result damage is generally not heat-induced, but rather caused

by nearly instantaneous dielectric breakdown. Usually damage results from surface or volume imperfections in the material and the associated irregular optical field properties near these sites, rather than catastrophic destruction of the fundamental

material structure. Most Semrock filters have LDTLP values on the order of 1 J/cm2, and are thus considered “high-power laser quality” components. An important exception is a narrowband laser-line

filter in which the internal field strength is strongly concentrated in a few layers of the thin-film coating, resulting in an LDTLP that is about an order of magnitude smaller.

As an example, suppose a frequency-doubled Nd:YAG laser at 532 nm emits 10 ns pulses at a 10 Hz repetition rate with 1 W of average power. This laser has a duty cycle of 1 x 10–7, a pulse energy of 100 mJ, and a peak power of 10 MW. If the beam is focused down to a 100 µm diameter spot on the surface of a component, the pulse fluence is 1.3 kJ/cm2, and thus it will almost surely damage a component with a 1 J/cm2 LDTLP. However, if the spot diameter is 5 mm, the pulse fluence is only 0.5 J/cm2, and thus the component should not be damaged.

Some additional general “rules or thumb” are useful to keep in mind. First, the LDT tends to scale with wavelength. For example, LDT at 532 nm should be about half the LDT at 1064 nm, since the energy of one photon of light at

532 nm is twice that of a photon at 1064 nm. Second, the LDT tends to scale with the square root of the pulse duration  . For example, a 20 ns pulse should have an LDT that is

. For example, a 20 ns pulse should have an LDT that is 2 times higher than that for a 10 ns pulse with the same pulse energy.

2 times higher than that for a 10 ns pulse with the same pulse energy.

cw lasers: Damage from cw lasers tends to result from thermal (heating) effects. For this reason the LDTCW for cw lasers is more dependent on the material and geometric properties of the sample, and therefore, unlike for long-pulse lasers, it is more difficult to specify with a single quantity. For this reason Semrock does not test nor specify LDTCW for its filters. As a very rough rule of thumb, many all-glass components like dielectric thin-film mirrors and filters have a LDTCW (specified as intensity in kW/cm2) that is at least 10 times the long-pulse laser LDTLP (specified as fluence in J/cm2).

High-power cw lasers often have “hot spots,” or portions of the laser beam cross section with significantly higher intensity relative to the nominal intensity. A good rule of thumb is to multiply the nominal laser spot intensity by a factor of at least two to allow for possible hot spots.

Quasi-cw lasers: Quasi-cw lasers are pulsed lasers with pulse durations in the femtosecond (fs) to picosecond (ps) range, and with repetition rates R typically ranging from about 10 – 100 MHz for high-power lasers. These lasers are typically mode-locked, which means that R is determined by the round-trip time for light within the laser cavity. With such high repetition rates, the time between pulses is so short that thermal relaxation cannot occur. Thus quasi-cw lasers are often treated approximately like cw lasers with respect to LDT, using the average intensity in place of the cw intensity.

Picosecond lasers tend to have relatively large duty cycles (~ 10–3), so the peak powers are not very large. Ultrafast lasers (  < 100 fs), on the other hand, can have very large peak powers, and the high electric fields

associated with these pulses directly attack electronic bonds of dielectric materials causing some very interesting effects. Yet the peak intensity LDT values required for these effects to cause significant damage are generally so high that

the laser damage is still dominated by thermal damage mechanisms associated with the average intensity.

< 100 fs), on the other hand, can have very large peak powers, and the high electric fields

associated with these pulses directly attack electronic bonds of dielectric materials causing some very interesting effects. Yet the peak intensity LDT values required for these effects to cause significant damage are generally so high that

the laser damage is still dominated by thermal damage mechanisms associated with the average intensity.

The table below summarizes the conditions under which laser damage is expected to occur for each of the three types of lasers.

| Type of Laser | Typical Pulse Properties | Laser Damage May Occur When |

| Long-pulse laser |  ~ ns to µs R ~ 1 to 100 Hz ~ ns to µs R ~ 1 to 100 Hz |  |

| cw laser | Continuous output |  |

| Quasi-cw laser |  ~ fs to ps R ~ 10 to 100 MHz ~ fs to ps R ~ 10 to 100 MHz |  |

Units: P in Watts; R in Hz; diameter in cm; LDTLP in J/cm2. Note: λ spec and  spec are the wavelength and pulse width, respectively, at which

LDTLP is specified.

spec are the wavelength and pulse width, respectively, at which

LDTLP is specified.

* The cw and quasi-cw cases are rough estimates, and should not be taken as guaranteed specifications.