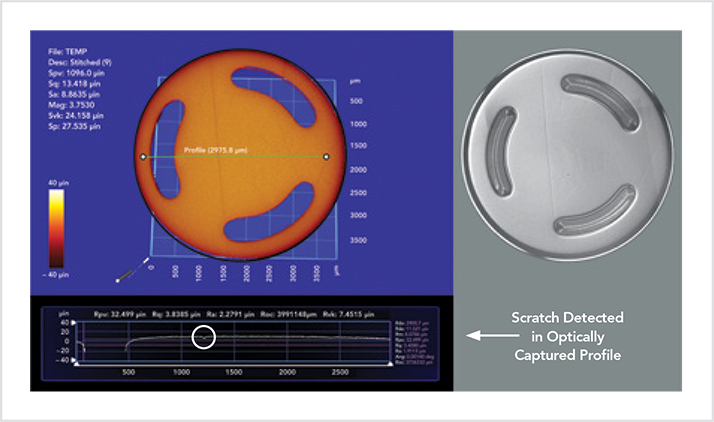

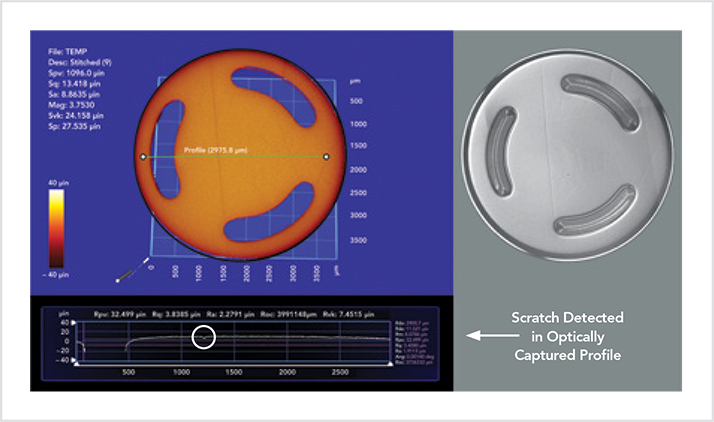

We’ll Get Up Close with Your Valve to Detect the Slightest Imperfections

Physical characterization of valve components is a critical piece of understanding the performance of your flow path. Looking closely at your valve’s components, especially the sealing faces, can lead to better insight into the workings of the design

and help assess performance. IDEX Health & Science utilizes sophisticated in-house equipment to get up close and personal with your valve during testing—locating the smallest scratches and imperfections.

Technology we use to analyze valves:

- A white-light interferometric based optical profilometer

- Scanning Electron Microscope (SEM)

- Additionally, we partner with certified outside laboratories for even more advanced analyses including Tunneling Electron Microscopy (TEM) and Focused Ion Beam Milling (FIB)

By leveraging our powerful tools, we can optimize your valve and flow path by:

- Evaluating valve components to understand the impact of seal wear

- Troubleshooting and understanding of valve material inconsistencies

- Examining wear characteristics to determine the best design of flow path

- Get insight into the workings of the design to help assess the performance

Partner with us to offer the highest value, shortest lead-time design considering material, design, manufacturability, and reliability for your custom rotary valve project.

Learn More and Download our White Paper