Build Smarter Chromatography Systems with the Right HPLC System Components

From connections to columns, IDEX Health & Science delivers precision-engineered components for accuracy, consistency, and reliable performance.

A smarter liquid chromatography system is one you can trust from the inside out. At IDEX Health & Science, we combine decades of proven expertise with precision-engineered HPLC system components, helping you design instruments that deliver consistent performance and reliable results.

Talk to an Expert Download the Chromatography Component Guide

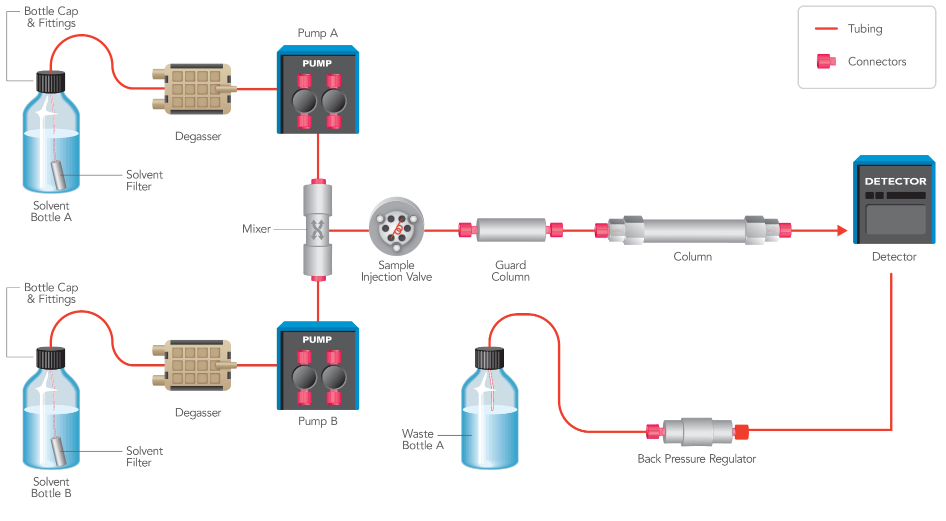

What components are part of a standard HPLC system?

An HPLC system is made up of several core components that work together to separate, identify, and quantify compounds in a sample:

Solvent Reservoir

Holds the chemical solution (mobile phase) that supplies the high-performance liquid chromatography system.

Degasser

Removes dissolved gases from the mobile phase to prevent bubbles, ensuring consistent flow, stable baselines, and accurate chromatography results.

Pump

Pulls the mobile phase from the reservoir and drives it through the system at controlled pressure and flow.

Injection Valve

Introduces the sample into the mobile phase with precision, ensuring consistent and repeatable injections for analysis.

Column

A tube filled with beads coated in a stationary phase that separates compounds by their interactions.

Detector

Measures the separated sample components as they exit the column with the mobile phase.

Recorder

Captures detector signals and translates them into a visual graph called a chromatogram for system analysis.

Waste Reservoir

Collects all mobile phase and sample components after they pass through the system, ensuring safe disposal.

Download our new Chromatography Component Guide and Get Expert System Support

Fill out the form to connect with an HPLC expert and receive our guide with detailed specs and component insights to support your system design.

*Required Field

Typical HPLC System

Every one of these parts depends on precise fluidics and optics. Small inconsistencies can lead to data errors, downtime, or reduced instrument performance.

How an HPLC System Works

In a typical HPLC workflow, the prepared mobile phase first passes through a degasser to remove dissolved gases that could interfere with flow. The pump then drives the mobile phase through the system and mixes it with the sample. Inside the column, analytes interact with the stationary phase and separate into distinct groups based on their properties. The detector measures these separated components and sends a signal to the recorder, which processes the data into a chromatogram. Finally, the waste reservoir collects the mobile phase and sample for safe disposal. This process enables precise separation, identification, and quantification of compounds within a sample.

Don't Overlook Fluidic Connections

Even the best-designed HPLC system is only as strong as its connections. A single leaking or faulty fitting can compromise results and lead to costly downtime. That’s why it’s critical to choose fluidic connections engineered for reliability and tested to the highest standards. IDEX Health & Science provides a broad portfolio of low- and high-pressure fittings designed to deliver secure, consistent performance in demanding chromatography applications. Shop Fluidic Connections

Why Engineers Choose IDEX Health & Science

When designing an HPLC instrument, reliable components are critical. IDEX Health & Science partners with OEMs worldwide to deliver:

- Precision-engineered components that safeguard accuracy and reproducibility.

- Broad portfolio spanning fluidics and optics for seamless integration.

- OEM-proven reliability to scale designs from prototype to production.

- Dedicated support from experts who understand chromatography challenges.

Ready to optimize your chromatography system?

Selecting the right components is critical to system performance. Whether you’re developing a new instrument or improving an existing design, our experts can help you choose the best HPLC system components for accuracy, reliability, and ease of integration.

![]()

HAVE A PROJECT IN MIND? START WITH A QUICK CONVERSATION.

Fill out a short form and our team will connect you with an HPLC expert who can help evaluate your needs and guide next steps.

Shop HPLC Components