Fluid Simulation for Life Science Instrumentation

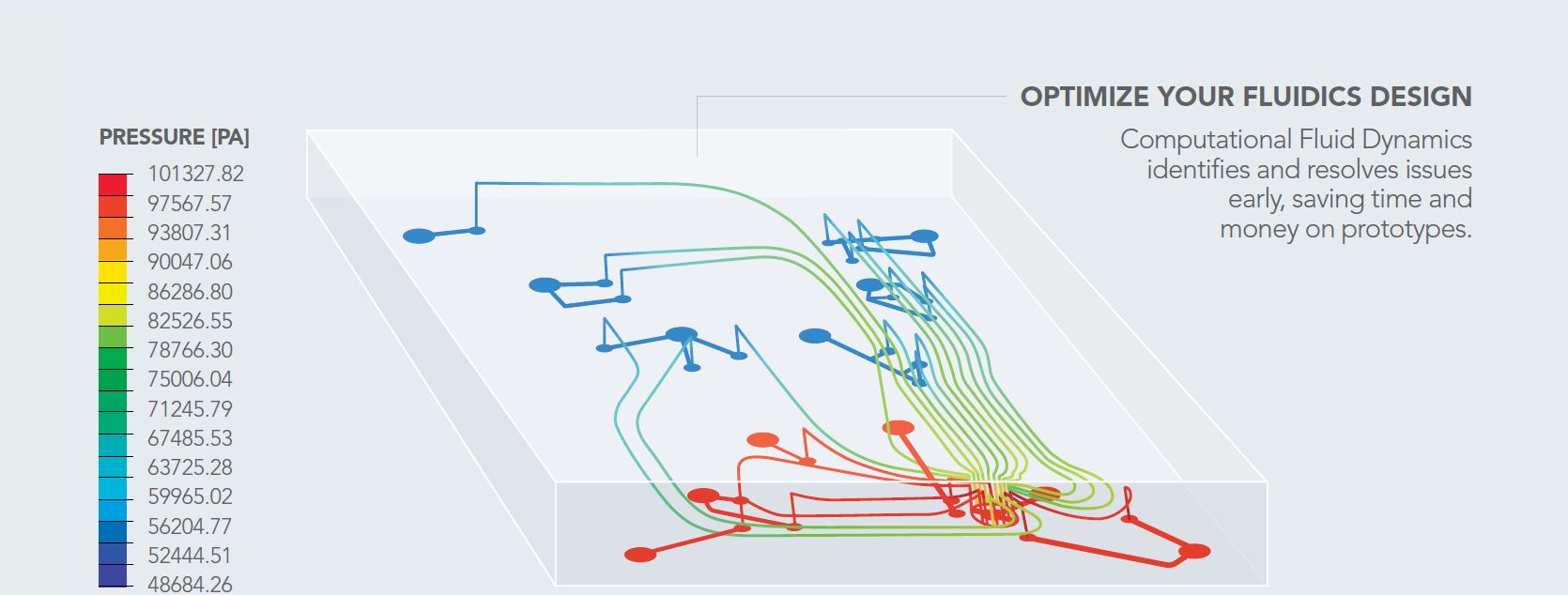

Many risk factors should be considered before manufacturing your design. Relying solely on physical testing to validate the design can be costly and will likely extend development timelines if an issue is uncovered. Fluid simulation for life science instrument development simulates how fluids will behave inside your instrument before manufacturing.

IDEX Health & Science offers instrument developers an option to analyze how their fluidics will operate before committing to expensive prototypes. Developers can characterize the functionality of their hardware in weeks instead of months in the prototyping feedback loop. Catching unexpected interactions, such as unintended pinch points, unswept volumes, and understanding boundary conditions of flow rates and backpressure can save months of manufacturing time and thousands of dollars.

Typical characteristics we look for include when using fluid simulation:

- Back pressure

- Flow rates

- Mixing

- Dilution

- Mechanical stress

- Unswept volume

- Cross-contamination

Contact an expert today to learn more about fluid simulation for life science instrument development for your next fluidics project.