Fluidics

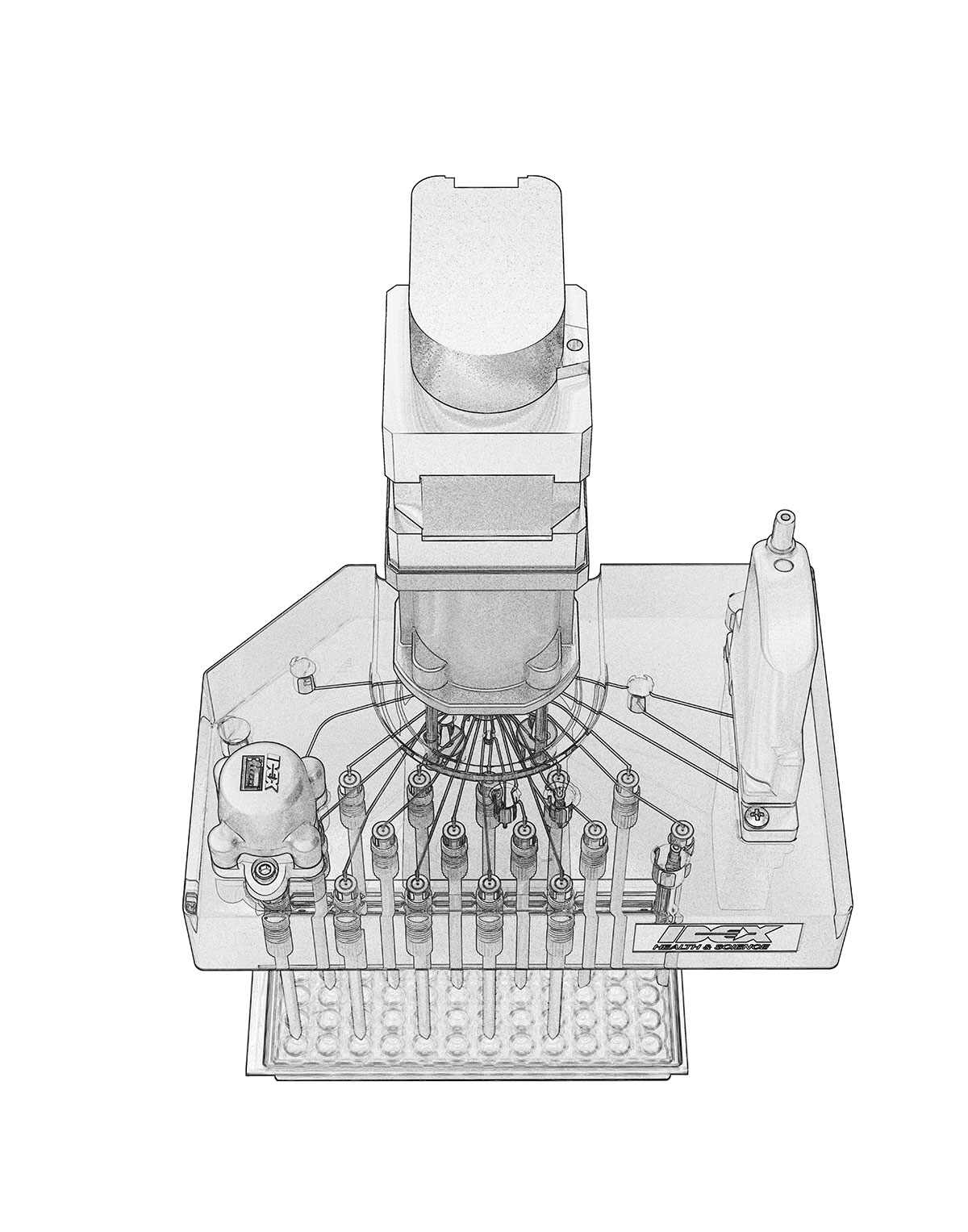

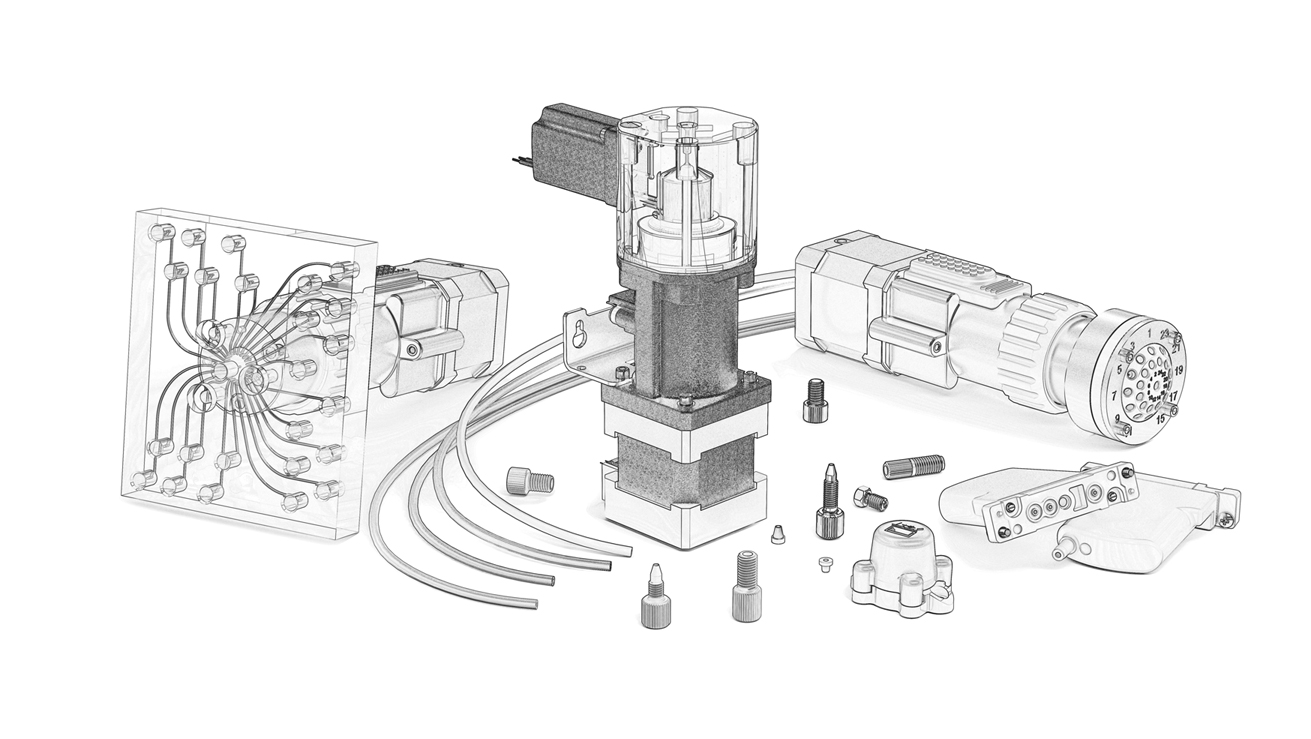

Ensuring the accuracy of synthesized oligos requires precise cycling of numerous reagents. Fluid management of this nature necessitates a complex, highly accurate instrument architecture. Partnering with IDEX Health & Science on the design of your synthesizer enables next-level reagent handling, allowing you to unlock the full potential of your chemistry. Our integrated approach to fluidic design incorporates valve on manifold subsystems, precision dispense pumps, and pressure sensors to increase throughput, minimize instrument footprint, and guarantee the reliability of your nucleotide output.

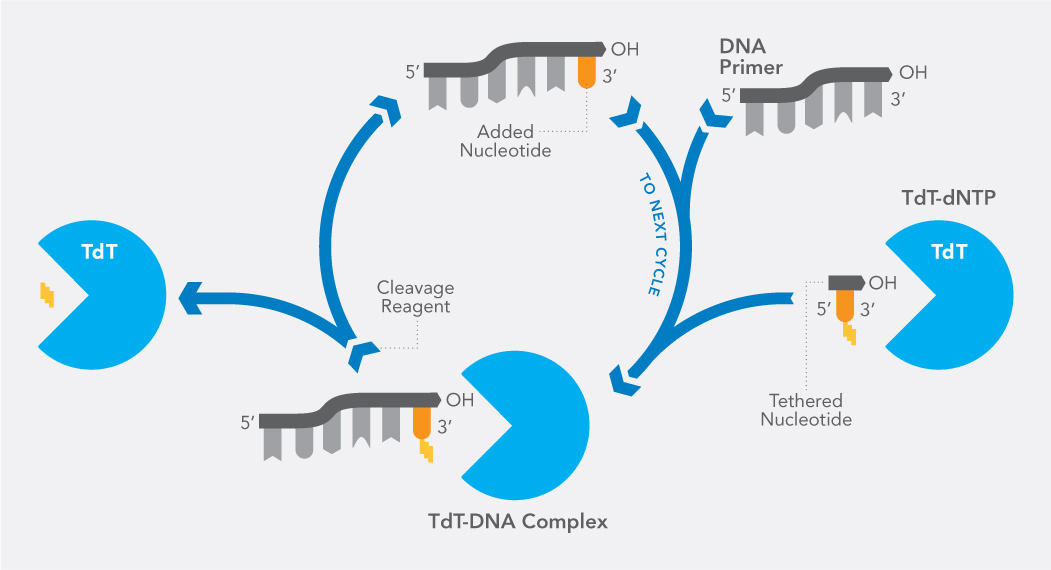

Whether your platform utilizes conventional phosphoramidite or enzymatic chemistry, the IDEX Health & Science durable seal pump solution confidently integrates into your instrument for maximum lifetime, handling the harshest reagents. Complemented with fully biocompatible valves and manifolds, a partnership with IDEX Health & Science will deliver system-to-system reproducibility for your platform.

Our 60 years of fluidic engineering expertise, computational modeling and performance testing tools ensure your synthesis system gets to market on schedule, generating high-quality oligonucleotides with minimal interruption.

IDEX Health & Science specializes in taking complex concepts to reality. We partner with you to remove the risks in controlling reagents, optimizing samples, and designing fluidic pathways, turning your theory into a working solution that advances science.

Download our Oligonucleotide Synthesis Fluidics Guide

Accurate and efficient nucleotide assembly is reliant on the performance of your fluidic architecture. Trust IDEX Health & Science solutions to perform consistently and reliably in your Oligo Synthesizer.

Click the icons below to learn about each of the fluidic components in a Oligo Synthesis instrument.

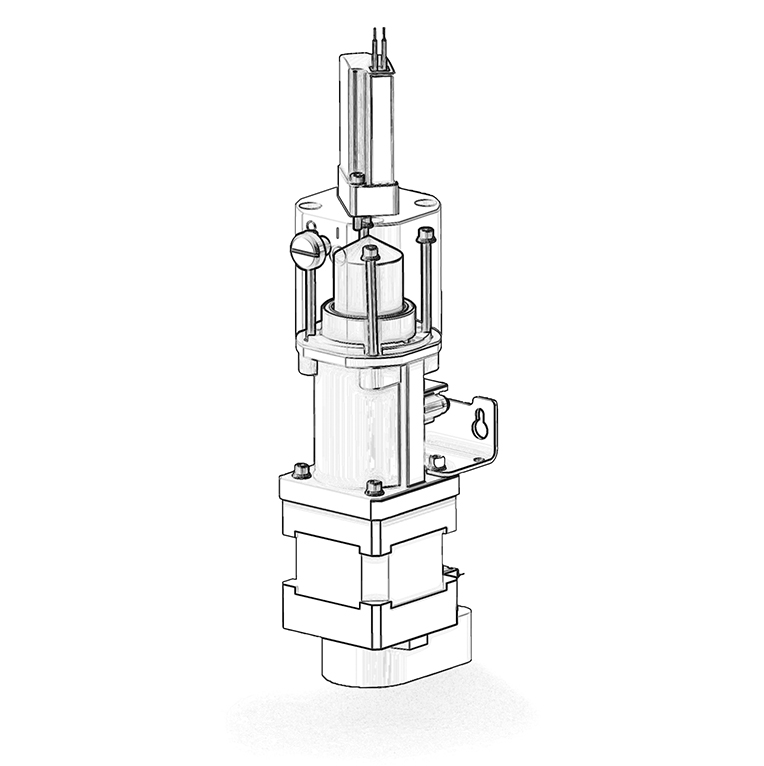

Our long-life positive displacement pumps deliver buffers and reagents with a high degree of fidelity ensuring accurate synthesis of your oligonucleotides. IDEX Health & Science durable seal pumps utilize highly tested, static sealing technology. Guarantee instrument lifetime and performance by replacing a high maintenance syringe pump with an IDEX Health & Science durable seal pumping solution.

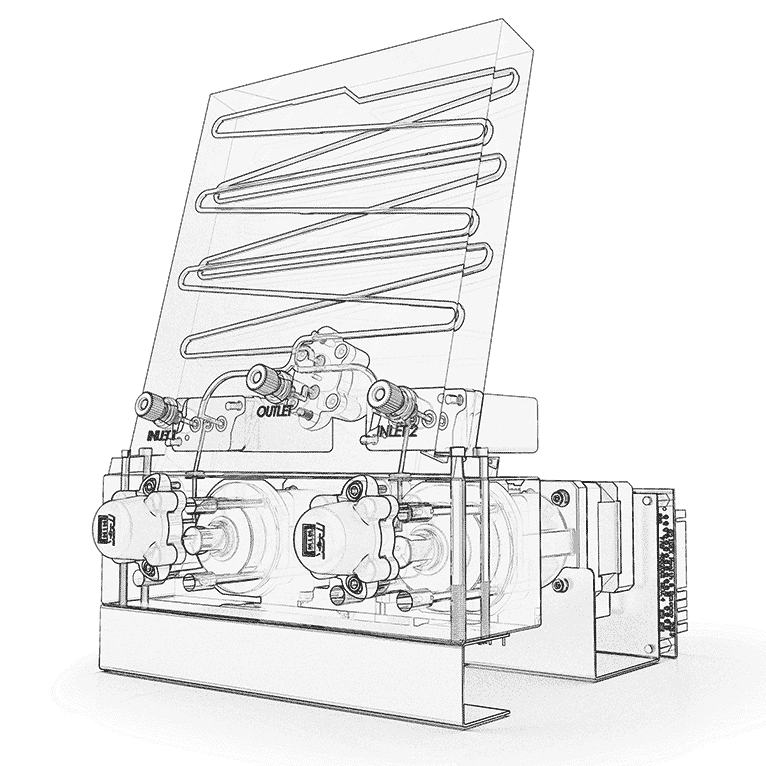

Our design team works with you to develop an optimized manifold for your unique fluidic system. IDEX Health & Science manifolds provide a reliable, easily serviceable, consolidated fluid path. With bonded manifolds and multiple material options, design possibilities are endless. Integration can include tubing & fittings, probes, valving (rotary and solenoid), pumps, degassers, and sensors./p>

Elevate your complex flow path with a valve customized to your needs. A single rotary valve can control up to 24 reagents with ease and negligible reagent crossover concerns. Valves are fully biocompatible and can be offered as standalone components or integrated onto a manifold assembly to meet the specific needs of your unique design.

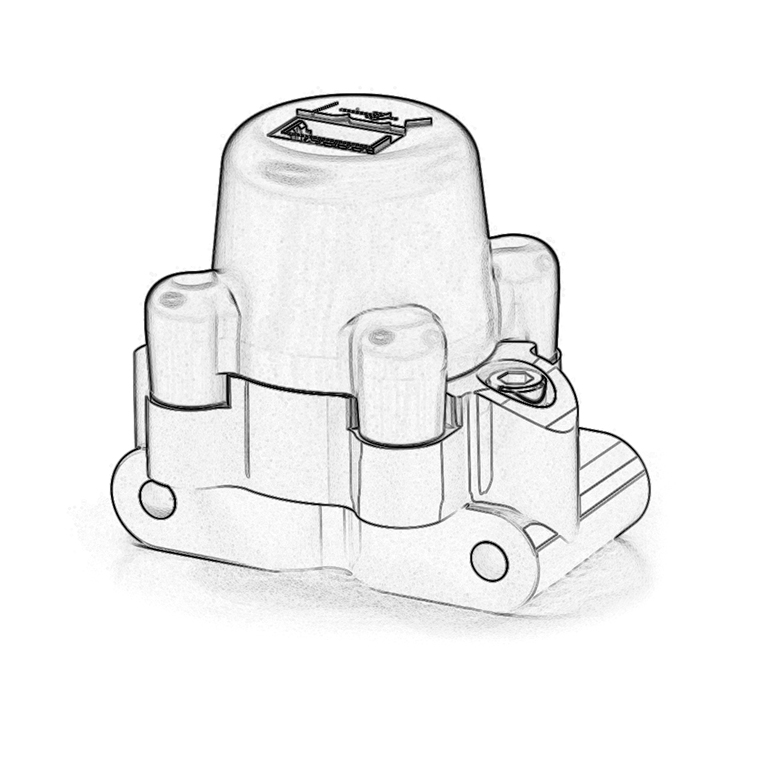

Inline pressure sensors monitor system performance, providing real-time diagnostic feedback to flow anomalies. The extremely low internal volume and a fully encapsulated MEMS sensor can be integrated standalone or mounted to a fluidic manifold for front-end or backend flow monitoring inside your system.

PEEK probes provide both the strength required for repetitive use and the biocompatibility you desire for your system. With several tip geometries available, your sampling and dispensing needs will be fully met with our probes at an economical price point.

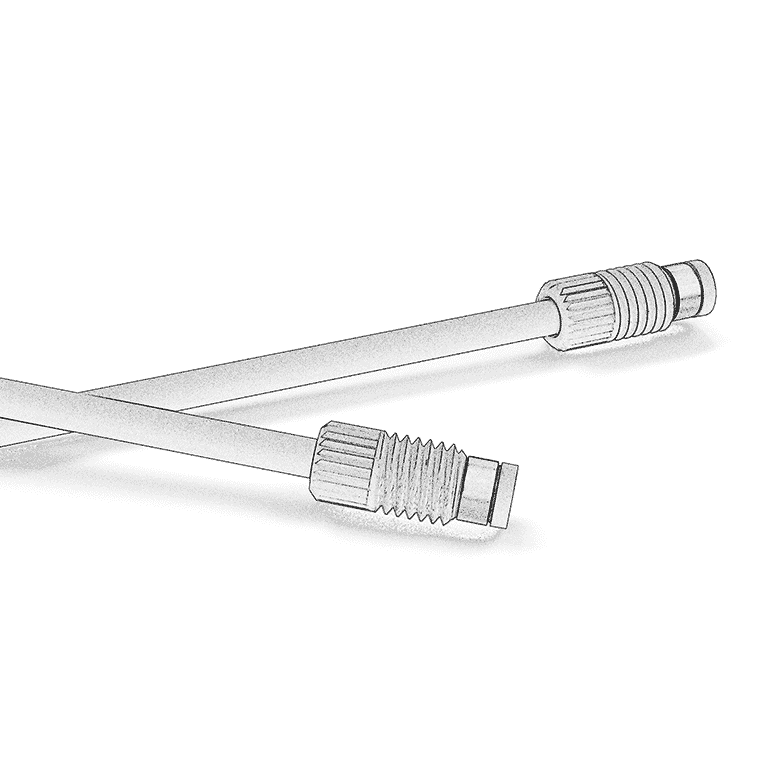

We offer a comprehensive line of custom tubing options that meet the increasingly demanding requirements of today’s high-performance analytical fluidic systems. We are the premier provider of intelligently engineered fluidic assemblies providing instrument developers simplified installation and serviceability of their complex fluidics.

We commonly precision manufacture internal diameters of our components, including valves and manifolds, to 500μm ±125μm (0.020” ±0.005”). Should you need smaller channel IDs we are happy to work with you on your custom needs.

Accurate tolerancing of all components along the fluidic path is critical to a robust, reproducible instrument design. At IDEX Health & Science we not only work with you to design a robust fluidic subsystem, we can also simulate your design to mitigate potential fluidic issues prior to embarking on costly and time sensitive manufacturing. We work with you to identify and correct problems before they arise, saving you valuable time in your early stages. Additionally, an integrated subsystem from IDEX helps you consolidate the number of SKUs you have to manage.

Our valve and pump products can include a PCB. We also offer our complimentary access to our Python Library for easy startup of your breadboard solution.

Our fluidics can be adapted for either case and what is best suited for your synthesis needs.

IDEX offers a range of testing to provide our customers confidence in their fluidic architecture. Typical testing includes pressure decay to guarantee leak free components and subsystems, flow occlusion to test for passage blockages, system pressure to ensure the fluidics function, as well as fluid volumes as specified per your application.

For complex bonded manifolds, IDEX typically utilizes PMMA (Acrylic) and PEI (Ultem 1000). PMMA is recommended for systems with inert reagents; PEI is better suited for applications utilizing more aggressive reagents (i.e. solvents). IDEX can offer a wide variety of polymers (e.g., PEEK, PVC) for simple, cross drilled manifolds. The same holds true for pumps; PEI is more inert, though other materials such as acrylic or PVC present cost benefits.

Lifetime is critical in managing the cost and servicing of your instrument, however there are other key aspects to consider. When dispensing precious reagents, precision and accuracy can make or break the cost of your assay. Every pump manufactured at IDEX is functionally tested to guarantee precision and accuracy and confirmed to perform as intended.